Okay, i’ve officially given up on today. So any responses here will be greatly appreciated and tested tomorrow lol

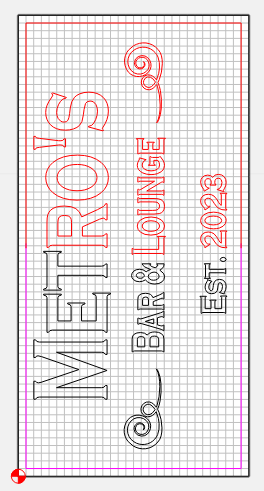

I’m gonna walk through the whole thing, my finish size for my sign is a 60" x 30"

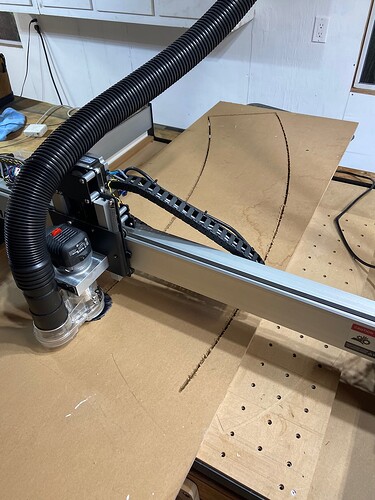

So I have my material pre-cut to 60x30, the X axis is a nonfactor since once i had it straight, i lined it with boards screwed into the bed

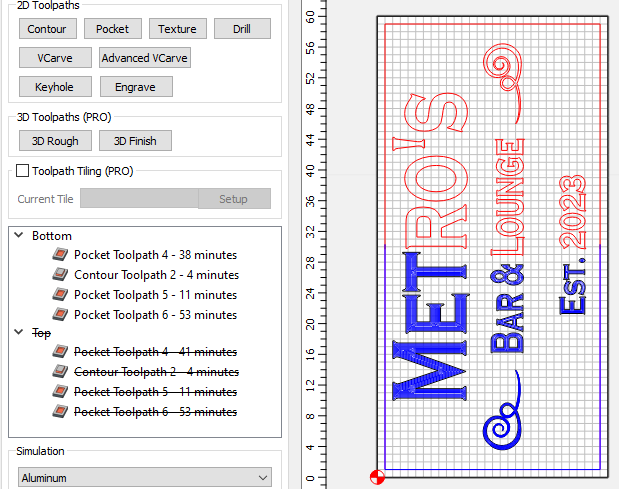

I have my file marked as 30" for height and 1" overlap

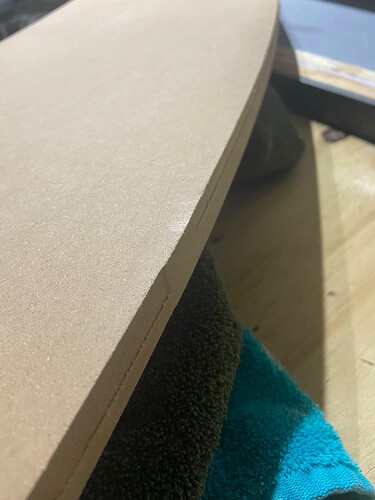

So i did my top cut first, at 30" down from the top of the material, and it worked well.

I began the 2nd part of the cut, the bottom, I had Motion home to previous X Y, and laid out my material to match that, right on the corner of my stock

First thing it did was bump the Y in the back, i assumed at the time because it was trying to travel back 31" (30" height, + 1" overlap)

It bumped and i restarted everything to have the X and Y remain accurate

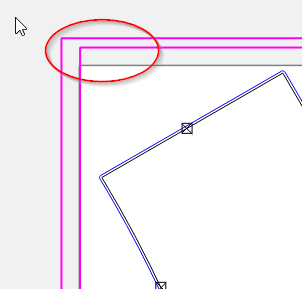

Assuming that it was travelling the inch, i started my Y 1" past my stock, in negative space. And it made a double line when it was supposed to recut the side of an R

What was i meant to do here? Because i’m just confused, if it was cutting the 2nd tile accurately, then why did it bump the back? If it needed the inch of travel, then why did it start a cut away from the area it was meant to start?

The Metro’s sign.c2d (488 KB)