Of course you are, but sometimes the road to success is long and windy

I assume you have already seen this great post from @WillAdams about the approach.

Disclaimer: I have the smaller SO3, with no access to three of its four sides, so I could never try tiling myself. Take everything I say with a grain of salt and suspicion. I’m replying because I may well learn a thing or two myself, as we collectively walk you through creating the correct CC design to do what you want.

I understand you want to cut this on a XXL, the first thing to decide is whether you will tile by sliding the large 48" long stock from the side of the machine, or from the back/front. Because then you need to align things in CC accordingly.

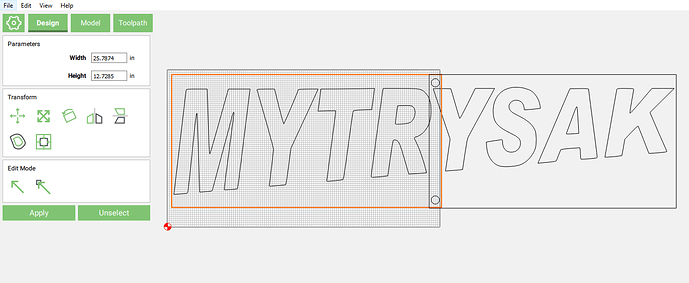

You current design looks like this:

- It’s setup to tile in the left/right direction, is that your intent ?

- The M looks very close to the left edge of the stock, is this intentional ?

- the circles are 0.3937" in radius, does that match the size of the dowels/registrations pins you will be using to align the stock ?

- you will need (at least) two more circles, on the left of the first panel

- those circles seem to be too close to the top of the second Y (they may get cut when you do the letter cutout)

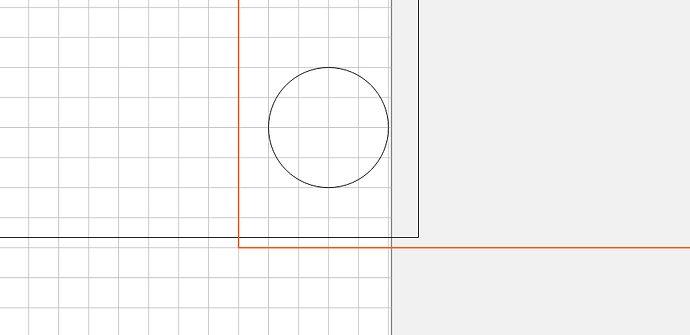

- the dimensions of the two panels do not quite match, the right one has a different height, so they do not align at the junction: