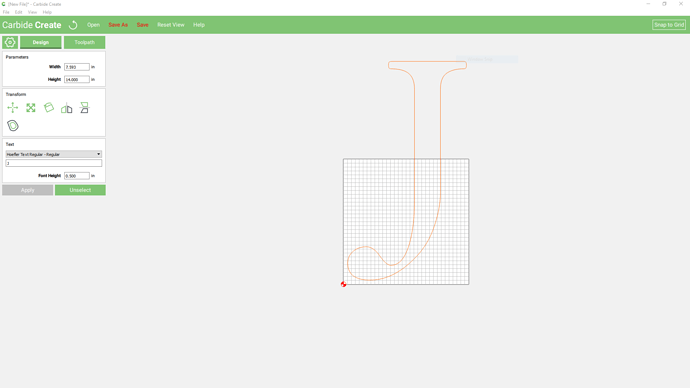

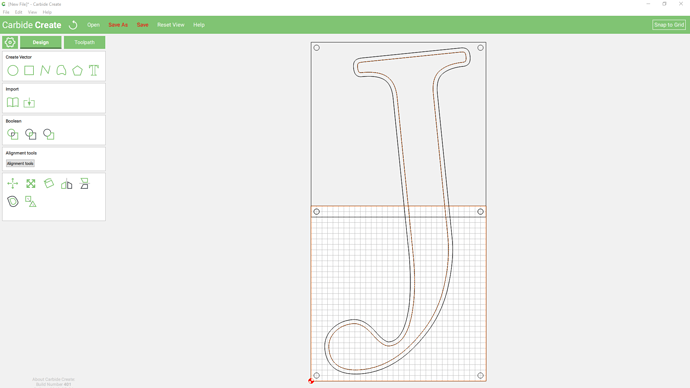

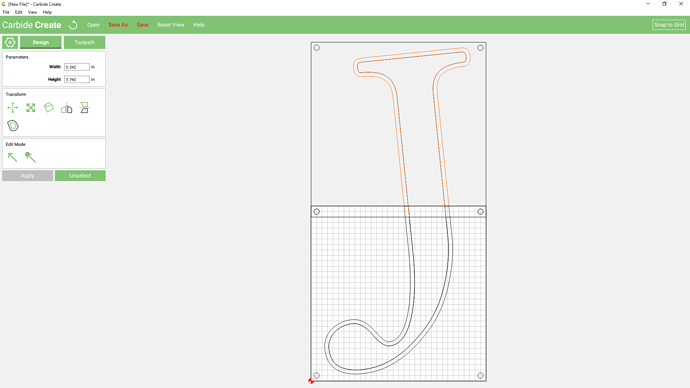

Okay, let’s imagine I want to cut out a 14" tall letter “J” on my Nomad:

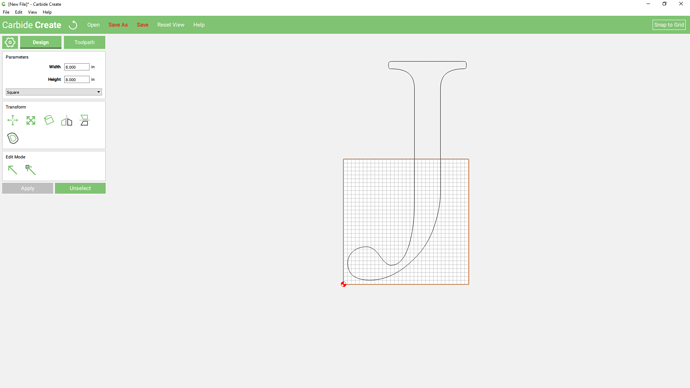

I would start by drawing an 8" or so square which defines where there overlap is going to be:

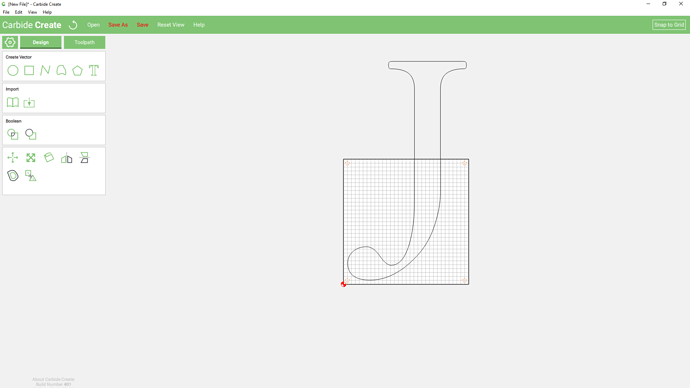

I would draw in some holes for registration pins:

I would then duplicate and drag the registration pins and square to define the balance of what needs to be cut:

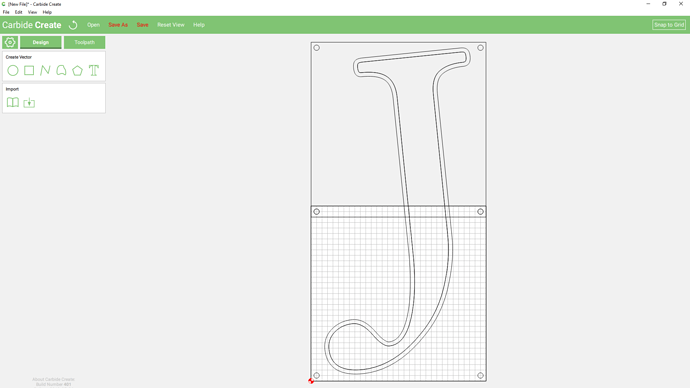

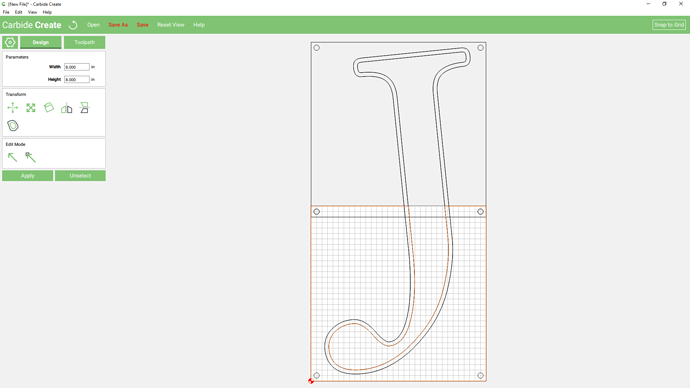

Then I would adjust the part I want to cut out so that it’s better placed and offset it by a bit more than the diameter of the endmill which I wish to use and duplicate the letter and do a Boolean operation to convert it into geometry (Duplicate the geometry twice including the squares (you’ll need two copies)):

Select one of the squares and the inner geometry so that the square is solid and the letterform is dashed:

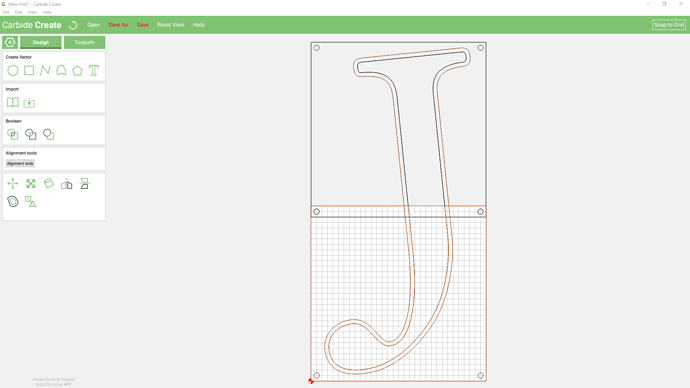

and do Boolean Subtraction:

Then select the new geometry and the offset geometry and do Boolean Intersection:

resulting in:

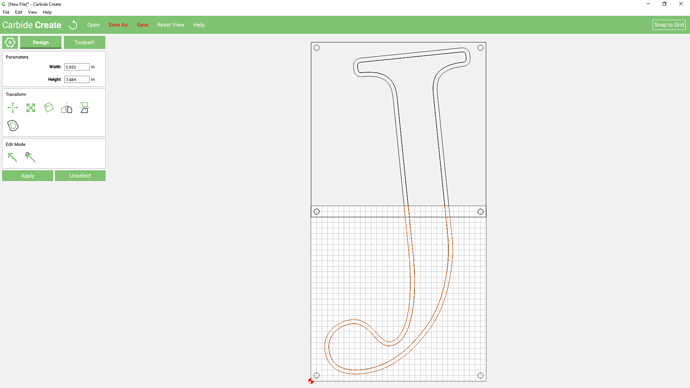

repeat for the other half of the letter:

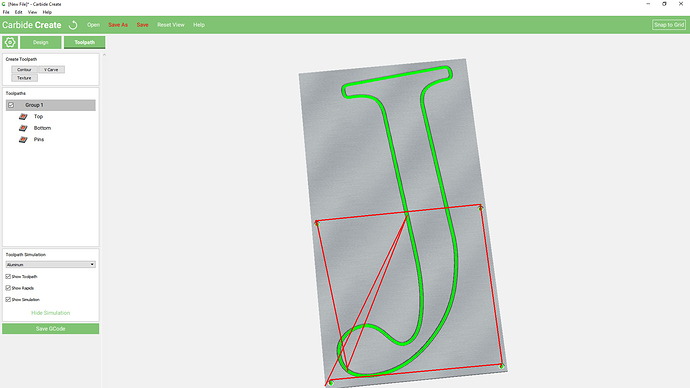

You can now assign toolpaths to the registration pins and pockets around the letters resulting in:

Attached.

tiling example.c2d (272.5 KB)