Just wondering if I can increase my feedrate on this job, time is 2.5hrs.

I surface my XXL spoilboard by taking off 0.5mm at a time with a 19mm cutter, 15mm stepover and it’s a <20 minute job, but that’s with the HDZ and a heavy spindle.

Liam,do you remember your feedrate, my bit is a whiteside 1"

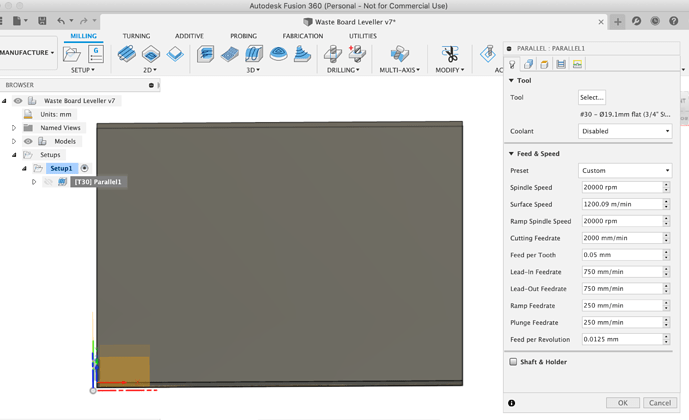

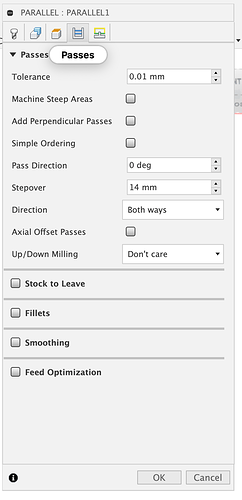

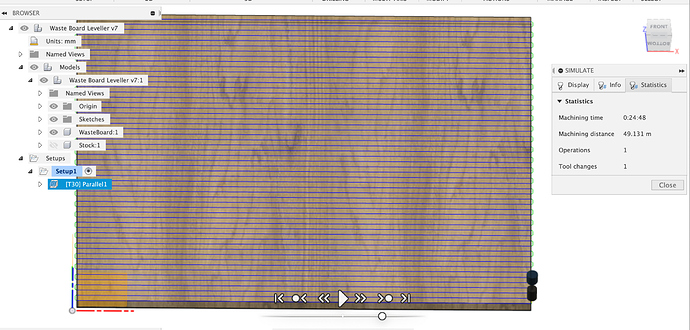

According to Fusion360 this is what I ran last time.

The simulation says 24 mins but I hit the feed override in about 30 seconds and ran the job closer to 200% speed as the machine was just not bothered, best advice is set up your toolpath, start the job, manually push the feed override up and listen to & watch the machine to see if it’s happy and could go faster.

My first spoilboard surfacing took over an hour and I’m pushing that time down each time I run it.

Is this what you were after?

Thanks, this is my second job, so just a little apprehensive about making a mistake

Yes, you have answered my questions thanks

Yep, your ears will get used to the sound of ‘happy cutting’ vs. ‘nasty vibrating mess’ and you’ll develop a feel for whether the machine is happy doing what you asked at the speed you’ve told it to.

The spoilboard surfacing cuts can go pretty quickly because we’re only taking a very shallow depth of cut which doesn’t load the machine up much, with deeper cuts the stepover and feed rate need to be scaled back (for wood at least).

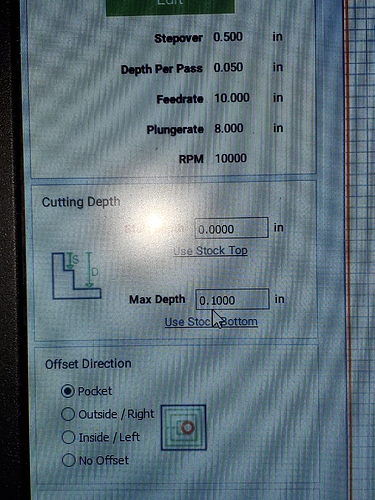

I use a Whiteside 6120 1 inch 3 wing cutter for spoil board leveling. I emailed Whiteside and they replied that I could use 100 IPM as a starting point. So I created a tool and set it for 80 IPM and a 50% stepover and take off 0.010 per pass. I only do one pass and look at the spoil board and see if I need to run the job a second time. To determine if you need to run again you can use a pencil and put squiggle marks all over the surface of the spoil board. After the first pass see if all pencil marks are gone. If they are you are done, if any remain then rezero and start the job again until all pencil marks are gone.

You may find that one corner is lower and/or higher then the other corners but just rinse and repeat until the spoil board is flat and all pencil marks are gone.

I just resurfaced my spoilboard yesterday using the Whiteside 1" 3 flute carbide surfacing bit. 8"/min for plunge is good, I used 100"/min and 14000 rpm. It came out very nice. The CC estimate was 25 minutes CM was under 20, for a XXL. Playing it by ear is key. slow it down for a pass, speed it up for the next and find the happy feed rate. Slower produced a more burnished finish, faster was less polished more of a velvety feel (this could be the “quality” of the MDF from the big orange box store).

Thanks for sharing. I have been manually trying different rates. The plunge on the bit is a bit scary. Your lower rate of speed would make me feel more comfortable.

This topic was automatically closed after 30 days. New replies are no longer allowed.