Hi guys,

I’ve been playing around with cutting small shapes from some thin aluminum sheet with my new pro xl and I’ve been getting OK results as long as i take things super slow with my 1/8’ endmill. One thing i’ve noticed is i seem to be having a hard time keeping my cut channels free of aluminum chips so my end results seem to be rather hit and miss. Right now i’m just vacuuming up the chips by hand while its running but it doesn’t seem to very effective at clearing the chips. I’m just curious what most people use for chip clearing, i’m guessing some sort of air blast system?

I’ve managed well just using a Sweepy 2.0 — if things aren’t clearing I sometimes have to turn the vacuum up a bit more than for wood, but otherwise it seems okay.

Thanks Will. I actually haven’t set up my sweepy yet as like to keep an eye on how the run is progressing since i’m still working through optimal speeds and feeds. I know part of my problem is im using 3003 alloy aluminum which i know isn’t very ideal for machining but I’m pretty confident i can get decent results if i can help keep my cut channel a little cleaner.

I use one of these attached to a 6 gal air compressor and it works well. Both the 4 and Pro have bolt holes on the left and you can mount this with one, I want to say it’s m4 or m5. I’m not using the misting feature.

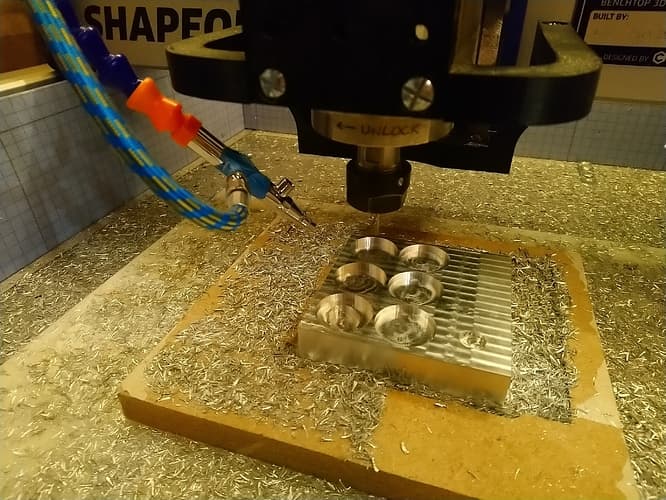

You get the idea:

Thanks for the suggestion. I’m in Canada and it looks like amazon ca has some similar kits. That definitely looks like a far more efficient way to clear chips.

One more vote for the air blast.

I was really annoyed by the sound of my air compressor though, so I finally went for an airbrush from Amazon

The airflow is just strong enough to take care of most aluminium cutting situations. Certainly enough for shallow profile cuts.

This topic was automatically closed after 30 days. New replies are no longer allowed.