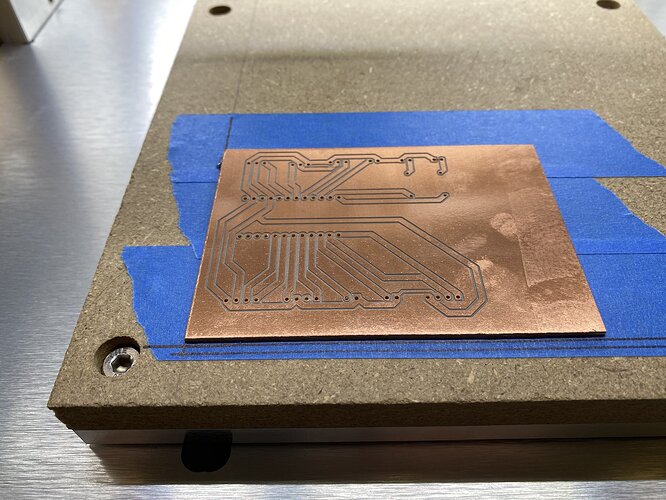

I’ve found that the circuit board needs to be pretty flat for fabrication. I’ve been finding the single sided boards to have some warpage so I’m using primarily the double sided pcbs from Carbide3D. Additionally, I 3D printed a plastic holding plate for the small 3x2 pub’s and then milled the surface flat. I use it not only to make sure the surface is true relative to the cutting head, but allows me to coat the PCB with mineral oil to reduce the amount of hazardous dust. After making the PCB I just wash it with dish soap.

3 Likes

Great tips!

I’ve been unable to get good, consistent results without autoleveling.

I recently setup bCNC just for PCB milling since it has autoleveling built in. First mill out of the box was near perfect. The UI certainly has a learning curve though.

My workflow is currently KiCad → FlatCam (BETA branch) → bCNC

Autoleveling probe is easily accomplished with the BitZero v2 and a piece of wire taped to the top of the BitZero and taped to the top of the copper stock. I plan on making a fixture for this eventually that will create a connection without the tape

4 Likes

Wow. I will certainly check those out. Thanks for the tips

This topic was automatically closed after 30 days. New replies are no longer allowed.