Why did you choose a 1"16" 4-flute endmill? Extra rigidity with the extra flutes while being able to maintain decent surface speeds?

what face mill would that be?

Pretty sure it’s this one

Note 3/8” shank

I had a set of 5 for $5 ones and it seemed like the most challenging thing to do. Speeds and feeds have to be on point

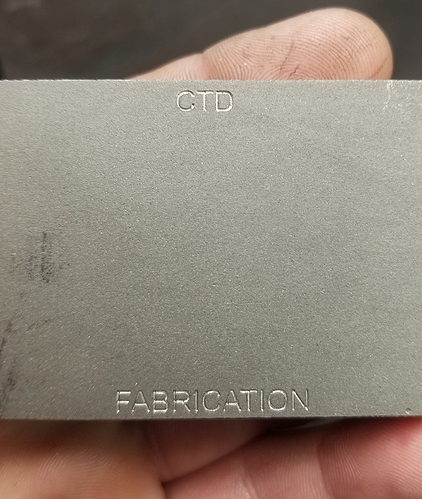

V bit engraving for science

0.001 chioload, 60 degree / 30ipm / 10k / 0.015 doc

Word on the street it means cant touch dis

Looks pretty crisp, is this with your 60deg kyocera bit?

Yup, probably could use a little more rpm due to the tip size.

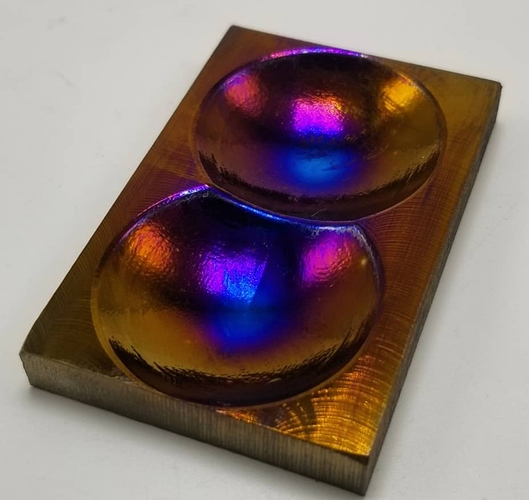

I put a little heat into it today, love how soft it feels on the machined side, nail doesn’t catch anything. Great pocket piece and thinking of making EDC items

Watch out Grimsmo, Vince is coming to town!

Haha, naw. Actually him and I have talked about shapeoko setup, really nice guy.

At the end of the day the only person you should be competing against is the person you were yesterday.

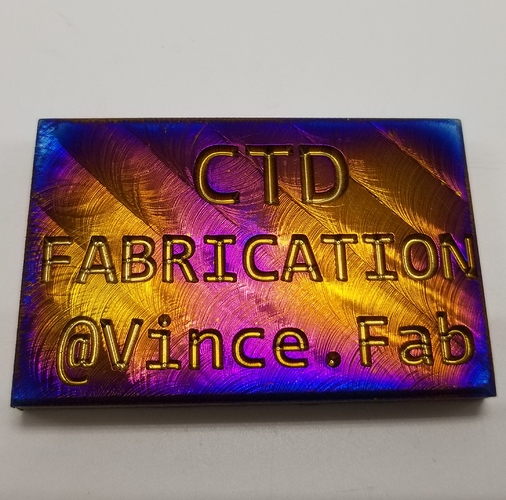

That’s why we’re gonna try deep V carving with carbide create next. Love hearing the machine run while I work on other projects, it’s the best employee

Can carbide create V cut titanium - survey says yes! But default settings need to be changed.

Purdy good purdy good

Lookin’ good buddy!!!

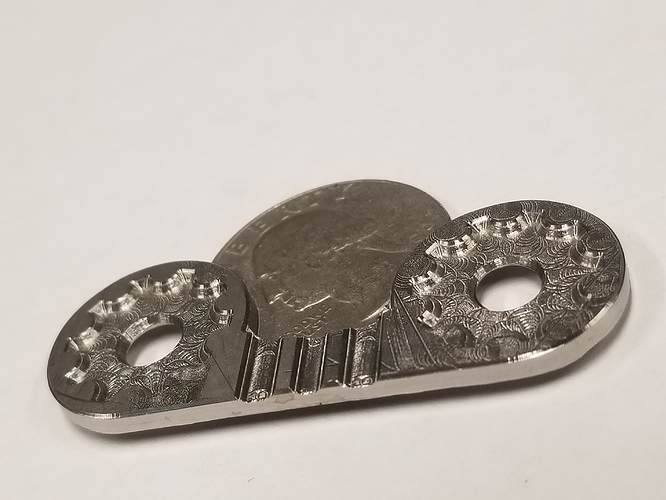

My elbows still ache at the thought of drilling that stuff by hand, thank goodness we have inexpensive little robots to do that for us these days. How big is that piece and how long did it run?

Dan

Whoa! Beautiful! What endmill did you try this with?

Part is 45x70x8mm and it ran for about 2.5 hours. Pretty conservative and I didn’t stand around to watch it.

Endmill used is the same 2 flute 60 degree kyocera, also still looks brand new.

Gonna setup the other side for another go at a double bowl. The local titanium supplier will like this lol, he didn’t think I was going to be able to machine it.

Another Win for the s3. What’s next? Tool steel? Maybe i’ll pick up some 304

Leaving racecars to make giant gummi bears

I think you’re onto something! But you know if you put your standard 1” gummi bear in a cup of water overnight you’ll get the same outcome right?

You didn’t happen to make the Good Guys show at TMS last weekend did ya? Not many tuner cars, but tons of beautiful classics and rat rods. They fired up a few old top fuel cars, I swear I felt a tear roll down my sunburned face, haha!!!

Dan

Straight off the machine, adaptive with a 60 degree V bit. Outer contour with the cheapest 2 flutes you can buy.

Geez Vince, making jewelry now?

Nice work! I guess you found the secret to milling titanium too.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.