You can chase your tail looking for zeros. Be as precise as you can but at some point spending hours to get thousands of an inch is not really going to matter. Get as precise as you can but quit chasing zeros.

I did not see what kind of machine you have but finding a common point to measure to and from is important. So for an SO5 and SO4 go from the corner of your spoilboard to corner. That is a consistent place to put your measuring tape. For an SO3 you can measure from the back inside corner of the steel frame to the inside corner of the front steel frame. Raise your tape measure up above the round over in the frame. Pull the tape tight because the sag in the tape will make you slightly off. Maybe get a helper to hold the tape measure on one end while you check the other end.

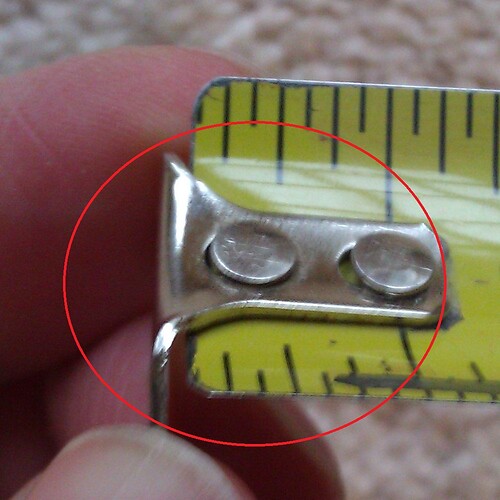

If using a tape measure there is a feature many people do not know or understand. On the end of the tape measure is an L shaped bracket. That bracket moves the exact length of that L bracket. That movement compensates for an inside and outside measurement with a tape measure. Also check that your L bracket is not bent. Many times a tape measure hits the ground and the edge of the L bracket can be bent. That L bracket should move back and forth smoothly. If it is hard to move back and forth that can also get your measurement off.