Hey all, I’ve noticed when I run jobs with multiple tools, the location along the Y axis where the Pro parks the machine for tool changes is not always the same.

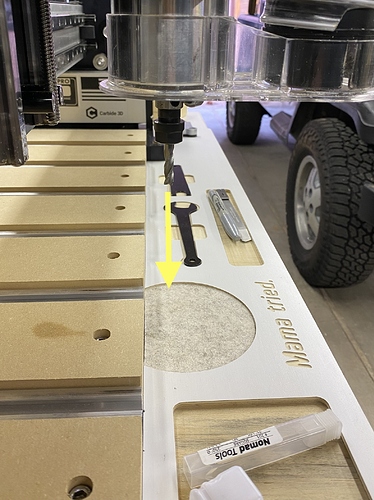

Once the bitsetter does its business the first time after initializing the machine, the bit gets parked at center front with the bit hanging out in front of the spoilboard (i.e. if dropped, the bit would land in front of the machine on a felt pad I placed). Subsequent tool changes during jobs, the machine parks the bit at center front, but with the bit over the spoilboard (actually over one of the t-slots), so if a bit falls out during a tool change, it lands not on the felt pad, but on the metal t-slot.

Is there any way to change the parking location for tool changes, or is there two locations that I can change one of to match the other?

The pics below will hopefully help illustrate the two locations the machine parks itself at during tool changes:

For now I’ve gotten in the habit of putting a tiny plastic tupperware container under the spindle when I’m changing tools to help keep cutters from falling to their deaths. This tool change location problem is more of a quality of life issue than anything serious.