Hello everyone. I make a lot of these deep (28mm or so) trays and wanted to post up my file along with some photos to see if there is a better way for me to make these regarding my toolpaths.

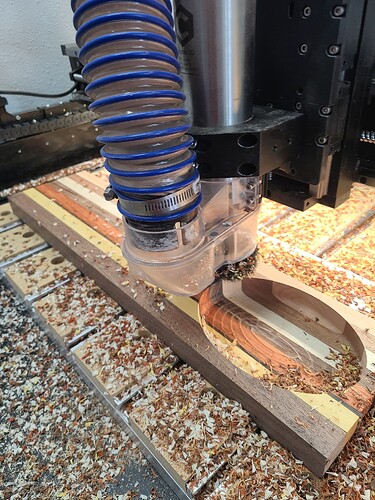

Right now my strategy is to cut the pocket in two roughing operations and then a final finishing operation. The reason for the two roughing operations is to allow me to adjust the Deep Sweepy for dust/chip collection, what little I can actually get. Having it prompt me for a phantom tool change gives me the time to adjust the Sweepy depth.

Once the pockets are cut I then run another pocket toolpath that clears out where I want to do the final cutout of the tray. This clearing toolpath is 7mm wide and spaced 1mm outside where the final cutting pass well be.

The next step is to profile the inner and outer edged with a 1/8 round over bit.

Finally, I use an extended length bit to do a finishing and cutout pass on the outside edges of the trays.

Here is my actual CC file for a set of my trays:

HexTrays.c2d (432 KB)

Does anyone see any improvements that I can make for either time savings or better quality? I’m not overly happy with the finish I get on the outer edge, even with the finishing pass.