Ever since I saw the contest from @Radiation at https://community.carbide3d.com/t/community-challenge-28-return-of-challenges/ I wanted to do a design like this using the Carbide Create new inlay feature, but I never got my head around how to do this in time for the contest… but better late than never.

(note: although I show some of the steps below, this is no a tutorial. While I normally show a lot of the digital steps in great detail when I write tutorials… this one is different. If this were youtube, I’d ask you to put in the comments where I cheated and skipped some complicated things… oh and to like and subscribe of course)

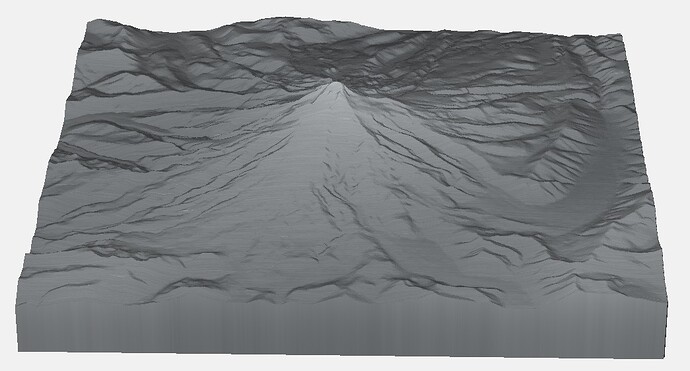

Things start of course with getting an STL file of the desired region from touchterrain, in my case the Mount Hood vulcano.

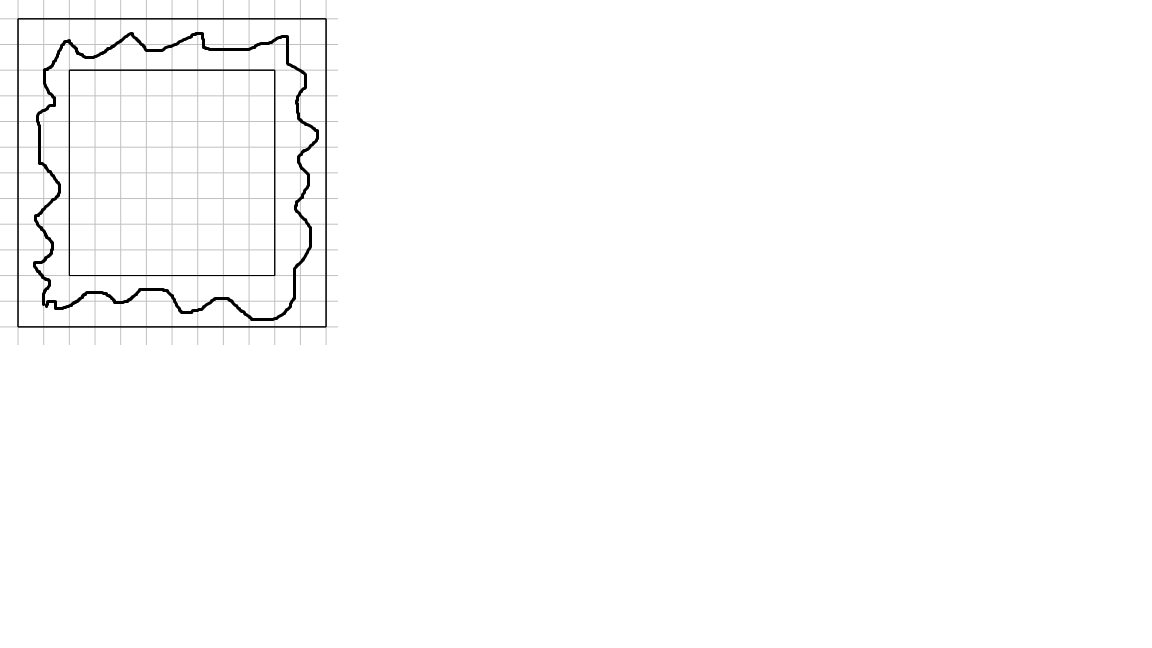

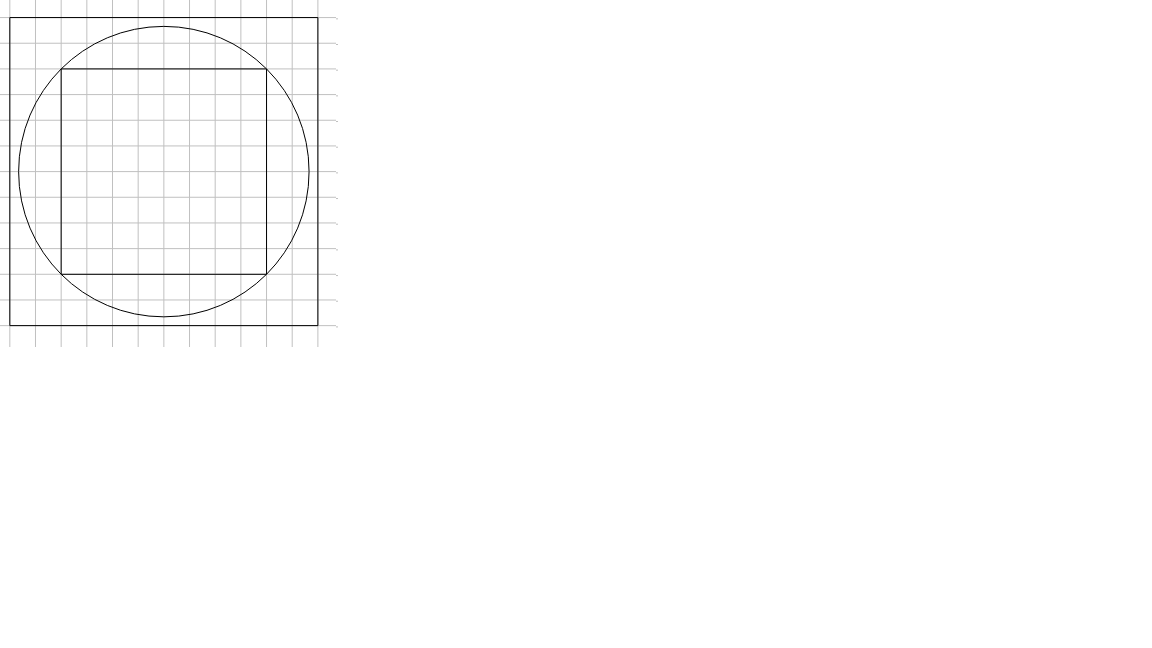

Then, make a simple 3D model in Carbide Create Pro, add roughing and finishing toolpaths

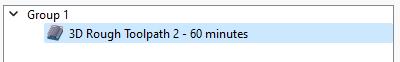

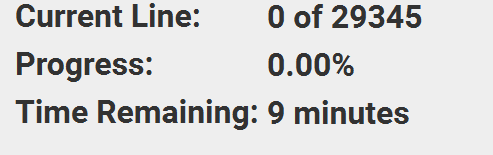

Wait. 60 minutes for roughing?? No way is that what I want.

[Opens F&S calculator. Measures cut length of bit #201. Watch TitansofCNC on youtube. Maximize chipload. Digital Banging Noises]

9 minutes. That’s more reasonable.

It gave nice chips but my dust collection did not manage to keep up.

As a video: Base Roughing - YouTube

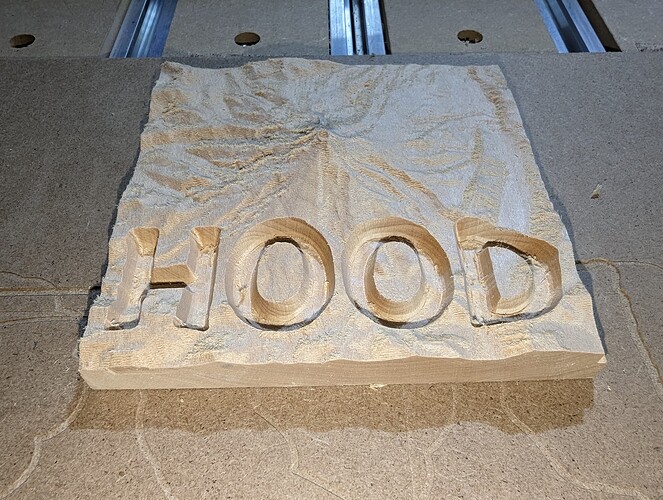

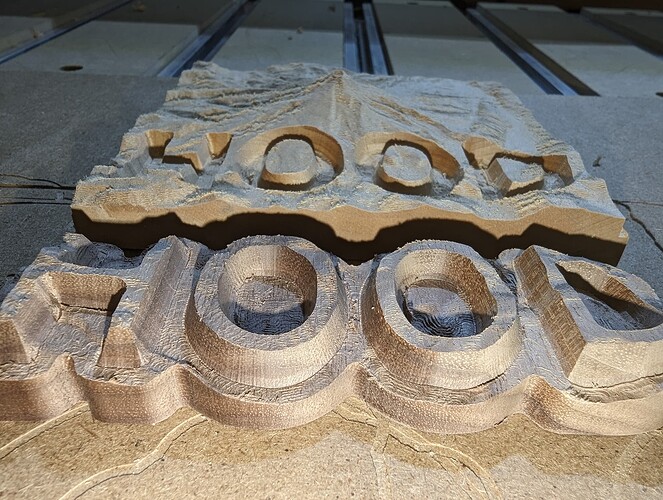

And the result:

And after an hour of watching my machine zig-zag using a 2mm flat endmill:

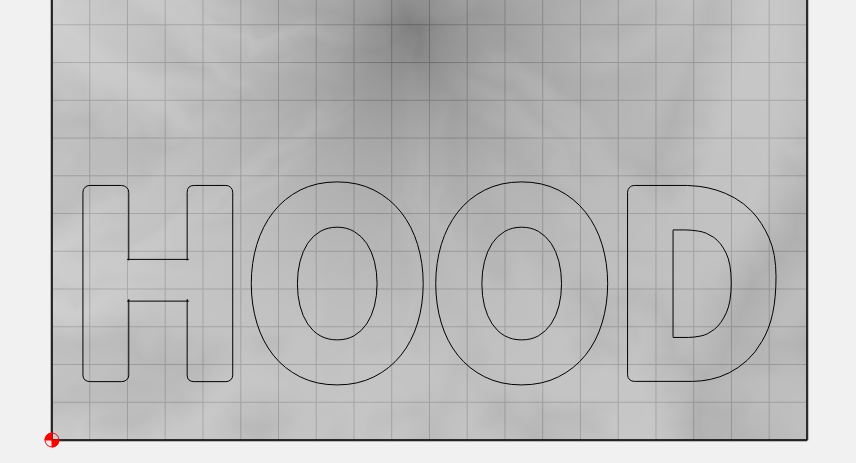

Ok that’s the topography done, now on to the inlay… Just a simple bit of text.

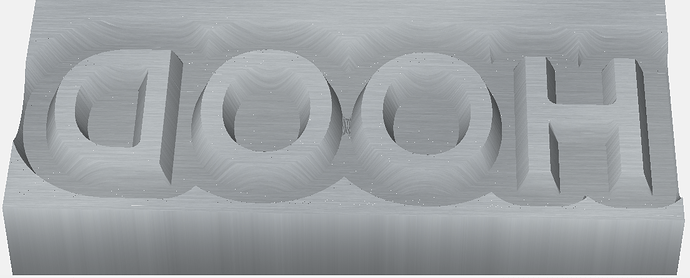

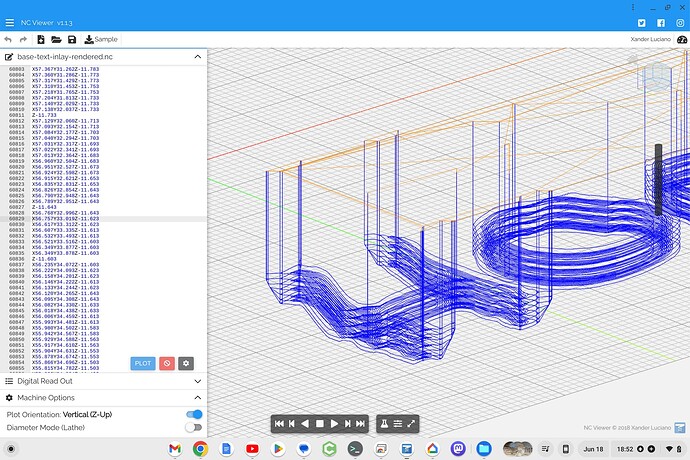

The preview looks good so lets carve it into the topography:

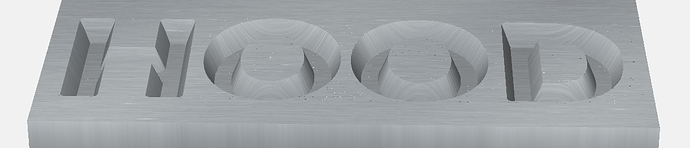

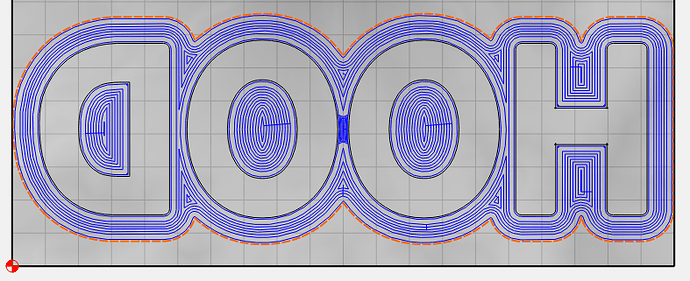

So on to the plug… lets not forget to mirror the design:

looking good… lets cut it

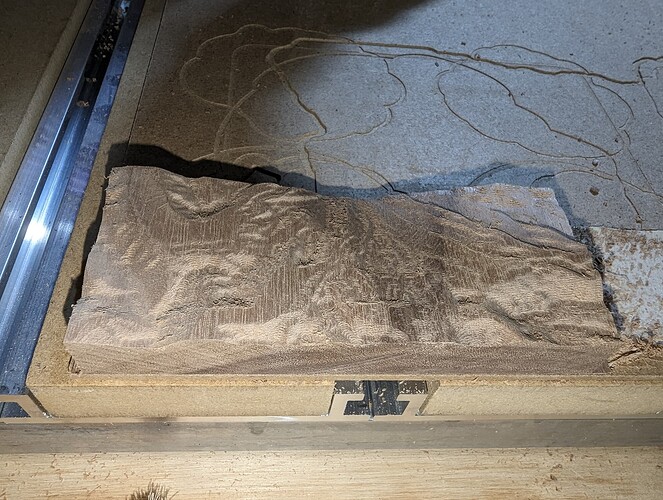

eh. rookie mistake, that’s not going to fit in the gap in the base.

[Cursing sounds. Digital banging noises. Pixie dust]

One first needs to cut the mirrored inverse of the base landscape

and THEN cut the plug toolpath on top of that

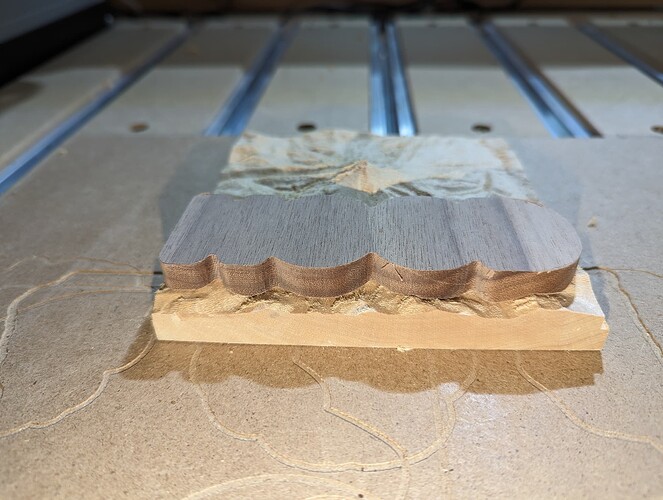

There. Much better.

This looks like it’s going to fit:

So time for the glue-up:

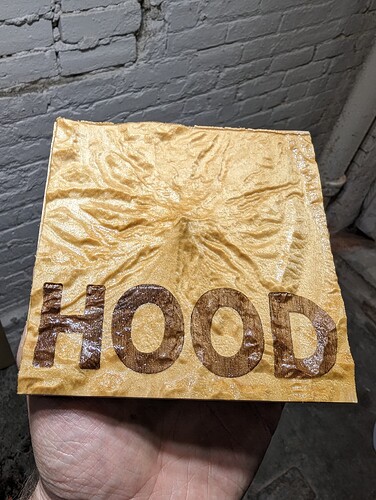

And after cutting off the top

[edit: the picture below is after I redid the cut with a 20 degree V bit]