Hey everyone, I’ve been running my shapeoko 3 now for a few weeks and I’ve ran into a problem. I’m trying to cut a lid that has rounded edges to fit inside of a matching box. Problem is that the lid either is too narrow or too long so it never really matches up precisely. I’m using carbide create and could upload the files if anyone could please help me.

The first thing you should check is if your machine is calibrated correctly.

More info here: https://www.shapeoko.com/wiki/index.php/Calibration_and_Squaring_the_Machine

Can you tell us more about the measurements? In other words, how big is the recess for the lid, and how big should the lid be? Are you getting consistent problems in the X or Y axis? Or both?

Bottom line, you need to first know if your designed measurements are coming out to match the actual cut dimensions.

The machine is calibrated and I’m using a brand new .250 bit. The workpiece is held down securely as well. I feel like the problem lies in my design. I had to make 2 rectangles and 4 circles then used the tool to merge them together for the lid. I did this so it would match the round diameter of the inside cuts on the box itself. The lid is 39w x 71h mm and the inside recess of the body is the same.

I made the circles for the door corners at 125 (half the size of the bit). I thought this would work but it looks like my door corners are still smaller than the recess cut into the box.

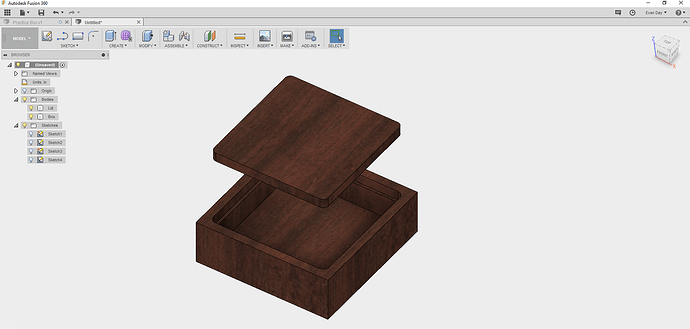

Okay. The only reason I suggested calibration was because you said you haven’t had your machine up and running long. I can’t speak to the design issue because I rarely use Carbide Create. I’ve got several small boxes I’m working on like yours and I use Fusion 360 to design them. I would recommend posting your Carbide Create file and some other folks will probably take a look at it.

Also what are the actual measurements of how your recess and lid turned out?

The cuts come out within a half of a mm and thats fine for what I’m doing. Thanks!

Really appreciate anyone taking the time to see how I can improve the fit on these!~

I took a look at your files. As far as I can tell, they look fine, but I don’t use Carbide Create for that sort of work. I am going to cut a similar design tomorrow (Sunday) so I will let you know if I have good results. Here is a screen shot of me designing a similar idea in Fusion 360. We will see how it does.

In my design I “shrank” the lid about 0.02" (~0.5 mm) on all sides to achieve a (hopefully) nice fit without it being a press fit.

Thanks for looking. I’ll be watching to see what kind of results you come up with. I guess I was trying for a press fit and maybe if I go slightly larger and just hand sand the door down I can achieve that.

Sorry no one else has taken a look at your files. @WillAdams, any thoughts on the original problem here? His Carbide files look fine to me. Still not sure how the actual measurements came out for you though.

Here’s how my cut turned out today from the Fusion 360 design above. Pretty good fit, although I had to sand where my tabs were. It’s not perfect because I still screwed up the work holding on my box lid and it got slightly messed up. But it will work for a simple project. I’m going to probably seal and finish the lid and box before I V-carve something into the lid. I had to sand the lid a little on one side / edge, because of the work holding issue, but if not for that I think it would have fit very well. Not loose, but not a press fit either.

I d/l’d the files and asked the balance of the team about them. Still waiting for folks to get back to me.

FWIW, I did the opposite sort of fit a while back, and it cut okay:

https://www.shapeoko.com/wiki/index.php/Carbide_Create_Photo_Tracing

aside from two other issues (used follow path rather than outside for the base, and made a similar mistake for the rounded cut along the bottom which in retrospect I ought not have bothered w/)

Thanks for all the help guys! I started to question my machine and the calibration but I never even checked the most simple thing…my bit was already getting dull. I popped in a fresh one and now my door is press fit. I also bumped up my door size very slightly and hand finish which takes a few seconds. Other things I did was slow down my speed of the machine and lowered my plunge. Everything seems smooth for now.