I am working on a small project to make some utility items for my wood turning. I love my Shapeoko for making shop utility projects.

Some people use face plates to rough turn bowls. I like to use face plates but not the traditional ones. My face plates are rings that have a dovetail groove in them so you can use your chuck to attach them to the lathe.

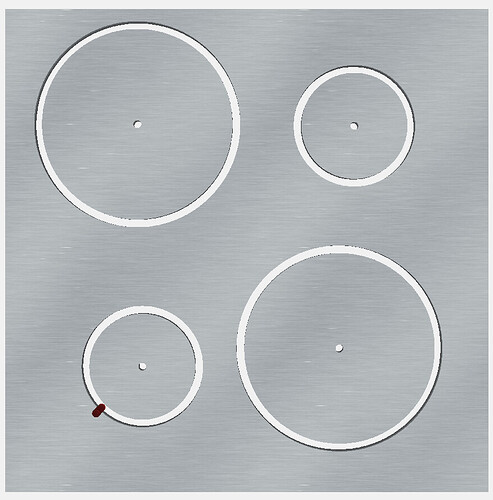

Here are some of those face plates.

Along with these face plate rings I use a Carter jig to cut a round cylinder on a bandsaw to save a lot of wear and tear on me during the roughing process. A prerequisite to most turning is getting the blank round before starting your design.

Carter has an add on that allows you to screw a face plate to the circle jig and cut your blank round. The add on is designed for threaded face plates. Since I dont use threaded face plates it wont work for me. So my intention is to make a wooden blank I can glue a wooden threaded face plate to the Carter jig so I can cut my blanks round. The blank would just fit inside my 100MM and 50MM face plates so I can spin the blank on the bandsaw and get it round. I would never use the bandsaw faceplate to actually turn because if it were to shear it could be a disaster.

On most blanks you draw a circle with a compass to establish how big of a bowl you can cut with a given blank. With the compass you have a center point and I use that center point to drill a .125" hole. With that hole you can get your face plate centered exactly on the blank. Without the hole you are just estimating the center and that works but with the 1/8" hole and a brass pin you get lined up exactly and not relying on your lying eyes.

Here is a simulation of the project. It will be about 1/2" thick and the exact dimensions of the inner ring of the face plate. Then I have the taps for 1/25" x 8 TPI to make a wooden threaded insert to glue to the cirlce cut on the Shapeoko so I can rotate the blank on the Carter Bandsaw Circle jig.

So to use these jigs I would place it on the blank and use the 1/8" brass plug to center the jig. Then place the face plate round it and screw it on the wood blank. Then plce the whole thing on the Carter jig to turn the blank round on the bandsaw.

I could just get traditional face plates but the centering is still an issue for them so this method could be used to center them as well if you make them the proper size for the threaded face plate.

Once you put the face plate on the wood blank you dont really want to remove it until the outside of the blank is roughes. As all of our CNC users know wood can be fincky about remounting and screw removal so keep your face plate attached until you are ready to turn your blank around to hollow out the center of the bowl.

I will update after machining and first use. Keeping my fingers crossed.