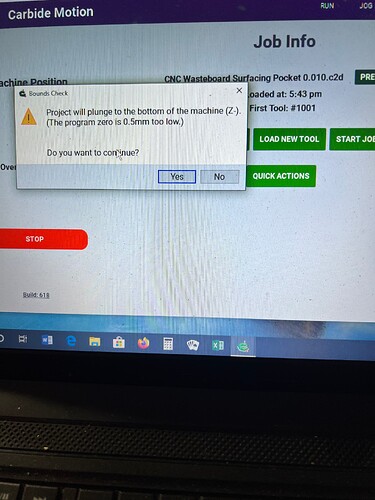

I know I’ve only had my machine for a few months, but I tried running my surfacing file and all of a sudden it’s warning me that I’m going beyond my machine bottom! I am using machine position numbers, using top of 3/4" material as my zero, and my bit buried itself in the center. I triple checked everything and it shouldn’t have done this. As you can see in my topic, I just upgraded to Carbide Create Pro. It’s like it doesn’t know where z is. Or at least it’s not using its numbers for Z.

Enabling a Pro license shouldn’t change anything save for adding the 3D modeling tab, and allowing some additional Toolpath options.

Post your .c2d file, step-by-step notes on how you are securing your stock and setting zero relative to it and managing all tool changes and a photo showing an attempt at cutting still in place on the machine and if possible, a photo showing where the machine was positioned when at zero.

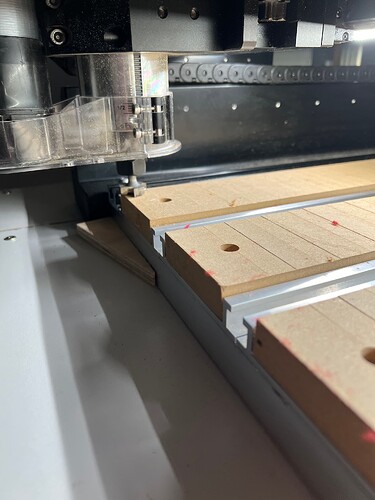

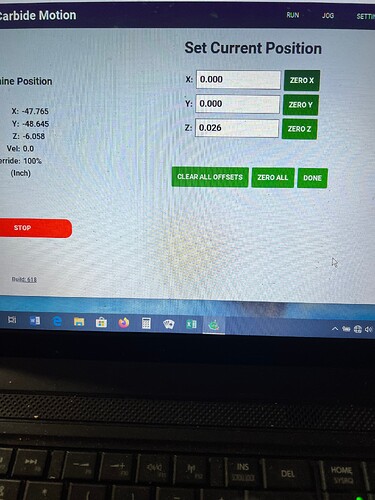

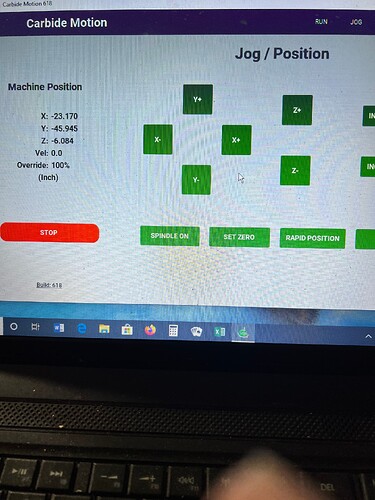

Attached is my Excel file showing my readings at all 9 rapid movement locations and my c2d file to surface my MDF boards. I set my Z based on the S depth and set it to zero, then I moved my router to my SW spot so that the edges of my MyFly bit was just off the corner and set my X and Y to zero. I included pictures of my screen shots during this process as well as the warning screen and

my ground ZERO.

Pre-surfacing readings.pdf (200.9 KB)

CNC Wasteboard Surfacing Pocket 0.010.c2d (44 KB)

I suspect that what has happened is that the MDF has been surfaced off multiple times, and is now so low as to trigger this warning.

Will, I assume that you haven’t seen my pictures. My slats are 3/4" thick.

Are all of them that thickness? It looks as if at least one is faced off a bit.

An alternative way to address this:

lower the spindle 1mm in the mount.

Yes, they are all nominally the same thickness. I’m worried about doing a project because I don’t know where it’s going in the Z. If it bottoms out the bit when running my surfacing pass, I don’t know where it’s going. My file clearly shows to only go down 0.037" from the top of the board.

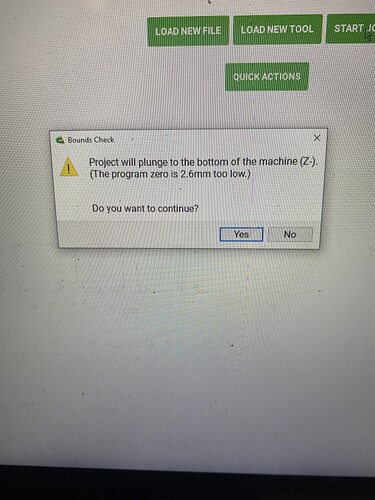

I am having this very same problem. I updated my Carbide, create and ever since I did that I’m getting the same window showing up telling me that my Z is too low so I checked everything and nothing seems to be off. I still get the same picture saying that my that the program Z is 2.6 mm too low. I’ve been through the setup several times still get the same problem

myan coaster.c2d (500 KB)

This is the file im using

Where/how are you securing the stock on your machine?

How are you setting zero relative to it?

Could you post a photo showing your stock in place on the machine and bit zeroed relative to it (assuming stock origin is Top)?

Will, I’m trying to surface my MDF so there is no stock to be held. I set my zero based on the highest number I got from the measurements I took. Refer to pictures and the pdf.

If the machine can’t reach as deeply as it needs to, lower the spindle in the mount by a bit more than the distance specified.

Will, it’s not a problem of it not being able to reach as deep as it needs. It’s that instead of only going down 0.037" as in my c2d file, it is bottoming out down to the metal of the pieces that hold the MDF slabs.

I have since tried another project which is going smoothly. That file it just doesn’t like. I zero with bit zero and manually same result.

Is your job setup to zero at the top or the bottom?

CullenS, Top. Look at my c2d file

Sorry, they haven’t ported CC to my phone yet ![]()

This topic was automatically closed after 30 days. New replies are no longer allowed.