You’re using a tapered ball mill, not a v-bit.

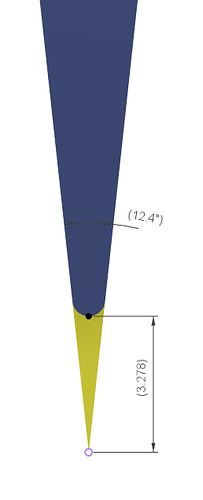

You’re Z-zero is too low and your angle is likely incorrect. The true point of a 6.2deg V-bit would be over 3mm below the end of the radius on the bit you’re using. The software you’re using has does not know the exact geometry of your endmill…it assumes a true point. Use a v-bit or adjust your Z-zero up 1/8" or so. Even then, it won’t be quite right because of the tip radius, but that is probably not big enough to cause much issue as long as you account for the Z-offset.

Tapered ball mill angles are assigned differently as well. If it was a V-bit, it would be a 12.4deg. That’s another MAJOR issue depending on how you set that up. If you have it set as a 6.2deg v-bit, you’re cutting twice as wide. Combine that with cutting too deep and you’ll never get a good fit.

Basically, a tapered ball mill is not a V-bit and isn’t a good choice for prismatic V-inlays.

Your 6.2deg tapered ball overlaid on what would be a 12.4deg V-bit.