Hello. I am making a simple home sign with my last name. When using a v bit (60 or 90) I set to stock bottom. It is carving very deep into .750 stock. any suggestions

How wide is your text? The V bit will go as

Low as it needs to for the edges of the V to touch the edges of the vectors.

You may want to try an advanced VCarve instead.

Are you using Carbide Create? If so, post your C2D file here so we can see what you are doing.

Simple vcarve should always use bottom of material. However as @CullenS said the vbit tries to touch both sides of the line and can go deeper than you want. You can punch right through thin material.

So if you want to limit depth use advanced vcarve and you can set the depth. You can use a flat end mill that will make flat bottom areas of the image has enough room. The advanced vcarve cuts the flat areas with the end mill and then goes around the perimeter of the lines for the vcarve part of the milling. If the lines are too close together it will just use the vbit to carve the image.

When you limit depth in simple vcarve you get unexpected results because the vcarve will not plunge enough to cut both sides of the line/lines.

Try advanced vcarve and look at the simulation. Also with a simple vcarve the simulation will show if you are going to cut through the bottom of the material.

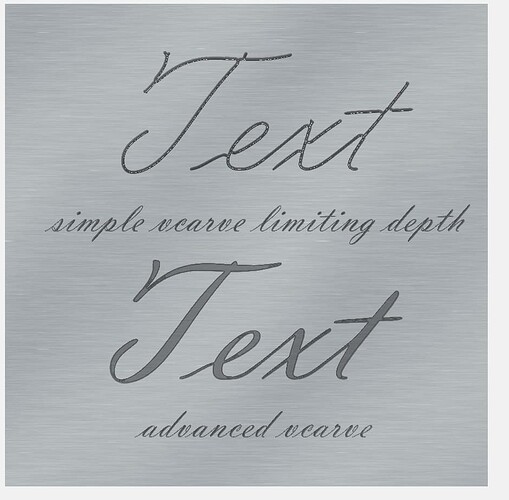

Here is an example of a simple vcarve and an advanced vcarve on the same text size. Because the material depth is .15" the simple vcarve cannot plunge far enough to fully form the letters. The advanced vcarve is looking good.

In this case the stock thickness limited how far the vbit can plunge. Also depending on the size of the text and slightly thicker stock I could have plunged through the stock on a simple vcarve.

Thank you, that is very helpful. My text is wide so advanced v carve would be the way to go. I know its personal preference but what end mill and v carve bit would you recommend? Also, what depth would be best for both.

The answer depends. When I paint the text I generally go .15" deep. If filling with epoxy I go .20" deep. The epoxy can go

.15" but if you over sand you can lose detail.

The vbit depends on how big the carving is. Larger I like 60 degree but if lines are fine or small I like 15 degree.

On flat end mill I use biggest that will work. Larger work can use .25", medium .125", and small 1/16 or 1/32. Advanced vcarve when you pick end mill too big to fit in flat areas only the vbit is called for and vbit will clear the flat areas. The flat end mill does a better job but the vbit can clear in small areas or fine details. Smaller end mills take longer to clear so try different bits and see estimated time. On simulation you can tell difference between vbit carving and end mill.

Thank you again. I will certainly try your suggestions.

This topic was automatically closed after 30 days. New replies are no longer allowed.