I am trying to learn to use Vbits for finer lines and details in my signs, however I cannot seem to make it happen. I am using a 90 degree vbit and keep trying to adjust the DOC shallower to get finer lines but it doesn’t seem to help. I have run it at .0700,.0500 and even tried .0050 but it never seems to make a difference.

I am obviously missing something here…I am using the 1/4" probe and probing in the lower left corner of the stock and setting it to the top of stock. I load the vbit when prompted and off it goes cutting but the DOC is shallower but doesn’t come as clean as I thought it should.

I am cutting 1/2’ PVC and I can get a finer line out of my .5mm ball endmill running it at .025…any suggestions would be appreciated.

V toolpaths should be allowed to cut as deeply as they need to unless there is a reason to change this — does your cutting match the preview?

Please post the file and provide the specifics of the stock which you are using — is it textured?

I am using 1/2" thick flat stock PVC that I lightly sanded and painted.

My thought was to use the v bit to cut out the mountains, trees and the camper to get crisp fine lines. I have tried the contour cut, the advanced vcut and both have not given the crisp line I have pictured in my head or what the simulation shows. ( I do understand that the simulation is just that and not necessarily what it will actually look like)

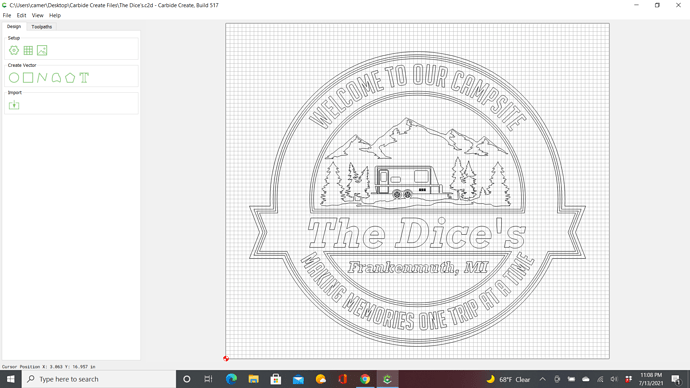

This is what I started with and changed the name and town/state

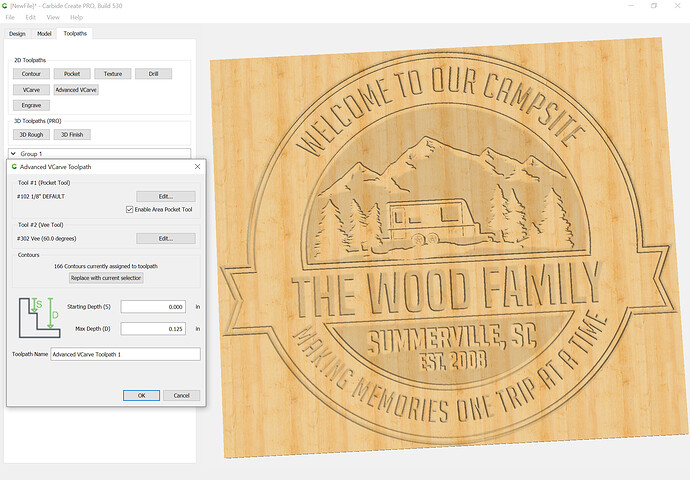

Did you try selecting everything and applying an Advanced V carving toolpath with the pocket clearing option?

No I didn’t since I was hoping to just outline everything. I wasn’t sure if I could use the vbit to outline like I did with the .5mm ball endmill.

I did try the advanced vcarve but didn’t select the pocket cutting option, the simulation shows it will cut just fine but when I cut it on a scrap piece it is nothing at all like the simulation.

Not on topic, but unless the family requested an apostrophe then you’re technically misspelling it.

If you have difficulty w/ a cut not matching the preview and the machine is mechanically sound, please send a .c2d file, generated G-Code, step-by-step notes on how you are securing your stock and setting zero relative to it and managing all tool changes, and a photo showing an attempt at cutting still in place on the machine to support@carbide3d.com and we will do our best to assist.

Have you tried using a contour cut with No Offset. I think this may do the trick. then adjust depth as is needed.

I may be wrong but it sounds good to me.

V-carves will always want to go to a depth to fill a gap between two lines.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.