Anyone have a good vaccum table desgns for shapeoko. I want to keep it low profile so i dont lose much z height.

@edwardrford worked one up and posted it to: http://www.shapeoko.com/forum/viewtopic.php?f=30&t=7480&p=58845#p58845

Here is a pretty good right up on one also. https://makezine.com/projects/make-41-tinkering-toys/shopbot-desktop-universal-vacuum-hold-down-system/

There are a lot of different ways you can build a vaccum table. I made a few attempts before I found the right set-ups (I use 3 different tables 1 with a basic hole pattern and 2 that are custom made to produce long runs of a specific part). A good pump is very important. I’m currently using a GAST G588NDX rotary pump that was reccomended by another member, but depending on what your application is you may need something different.

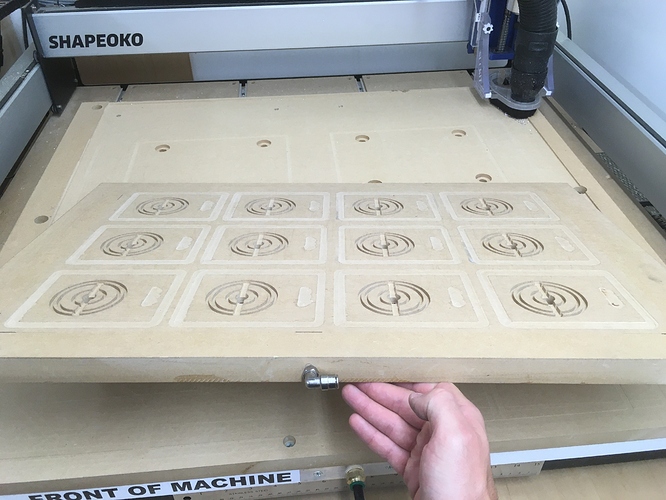

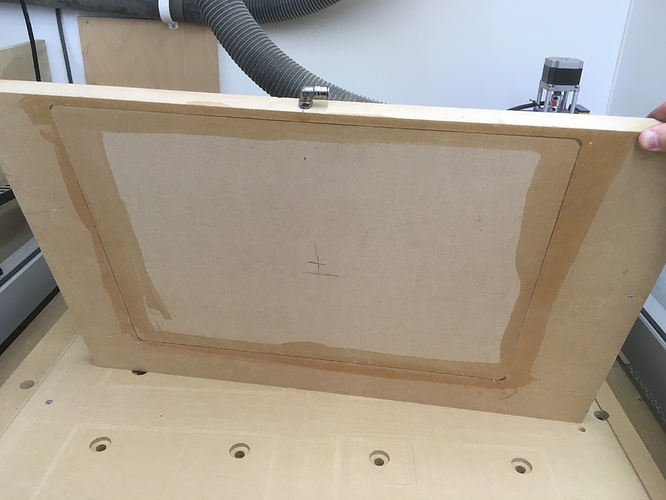

A single piece of 1" MDF can be used (pictured), here I ran a two-sided job to machine the connected pockets from one side, then flipped to machine the top holes and pockets. Afterward I sealed the inside and glued a 1/4" piece of MDF to close up the unit. Currently the push-to-connect hose fitting is epoxied into the edge of the board, a weak point in the deisgn, but it works for now.

I’m curious as to the advantages/disadvantages of using a vacuum pump vs something like a shopvac in the vacuum table design where getting to a full vacuum is not really the goal.

A shop vac uses the flow of air to keep the motor cool during operation. If you create a seal while using a shop vac air flow will stop and burn out the unit rather quickly. A rotary pump is designed to create a seal (vaccum) and hold it as long as the pump is running.

My set-ups allow me to hold down thin aluminum sheets, hence the desire for a good seal. for jobs out of thick aluminum or wood. I use the blue-tape and glue method.

What are you trying to hold down with a vaccum table?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.