As I’ve been working with signs, I think having a vacuum jig would be extremely useful. I wanted to see if my thought process makes sense. Please see the figure below. I’ve been thinking of getting the rockler vacuum pump and pods. I think I have a jig that allows for a low cfm vacuum pump while also having the benefits of a solid mating surface (no z change under downward load). You’d lose some of the benefits if you use an upcutting mill as that could break the suction of the vacuum pods.

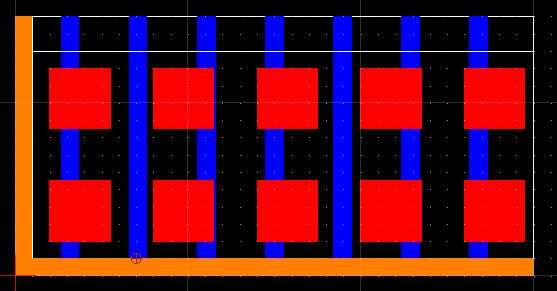

The jig would be made of 1.5" mdf after lamination. It’d be machined to have the alignment square in orange. I’d then have holes cut out in red to allow for multiple arrangements of pods. The jig surface will be the remaining lattice and the plane height will be such that the foam from the pods would stick slightly above it, but under vacuum, the part references the mating surface. I can then have some holes and counter bores for the t-tracks in blue. All plumbing for the jigs will be through slots on the bottom side of the jig.

Thoughts? I don’t own the vacuum equipment yet, but if this idea has merit, I’m willing to invest.