How do I Vcarve 45 degree edges in Carbide Create ?

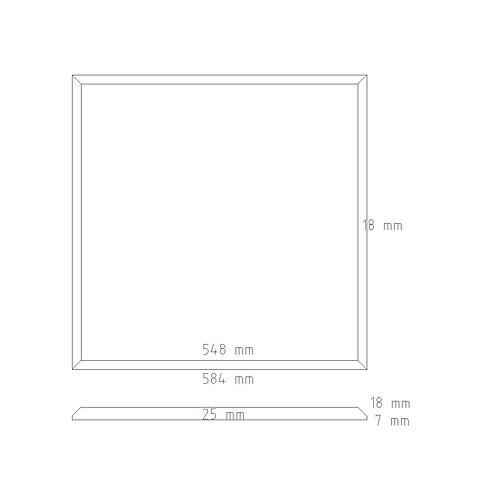

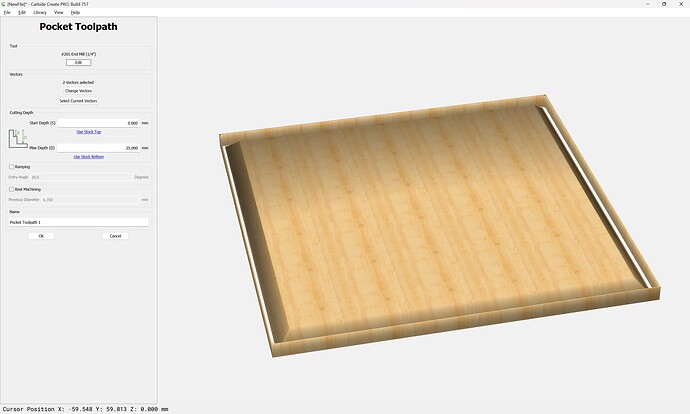

Plate is 584 x 584 x 25 mm bottom, 548 x 548 mm top. Depth of Vcarve is 18 mm.

I have a 7/8 inch Vee (90 degrees). Should I get a bigger Vee i.e. 1.5 inch ?

I just bought such a larger V endmill because I got tired of what is noted below.

it was kind of pricey.

To avoid that expense…

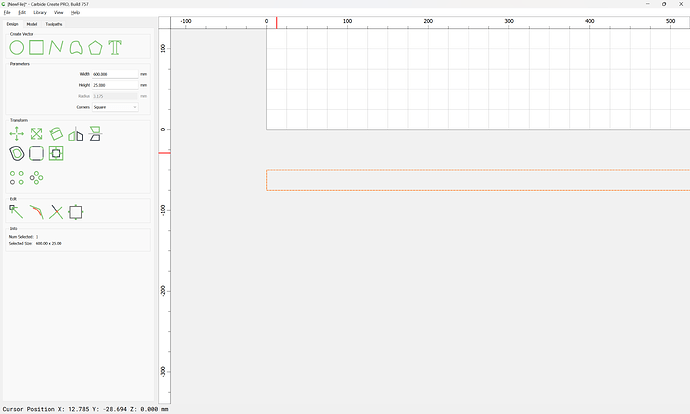

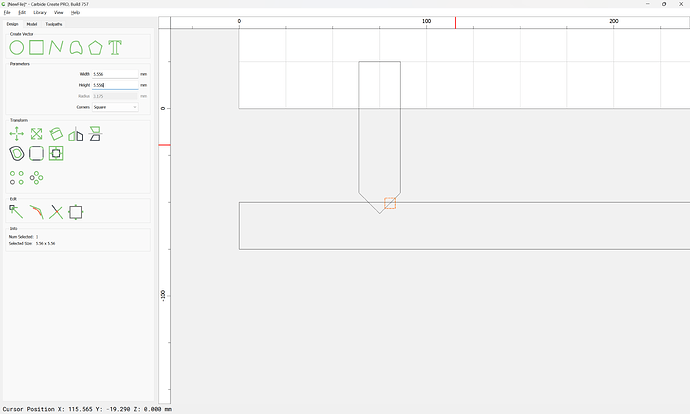

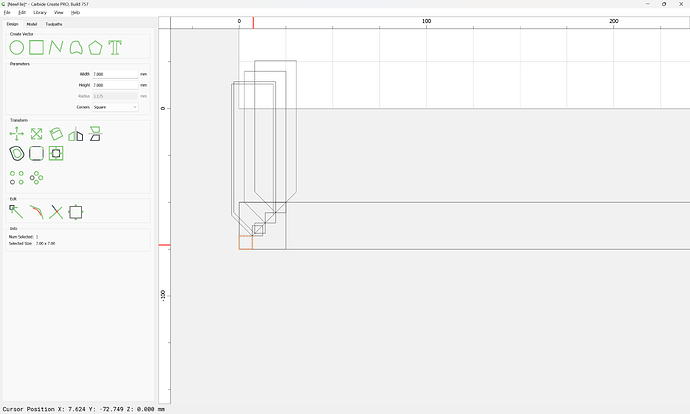

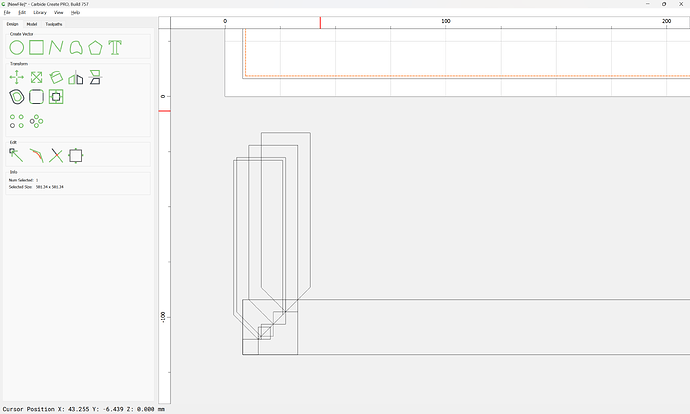

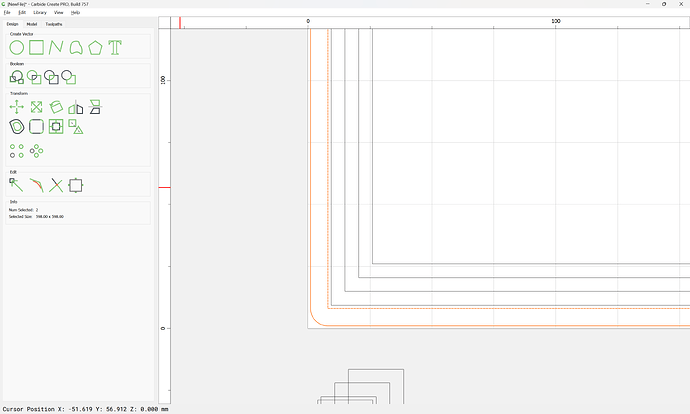

Draw the stock up in profile:

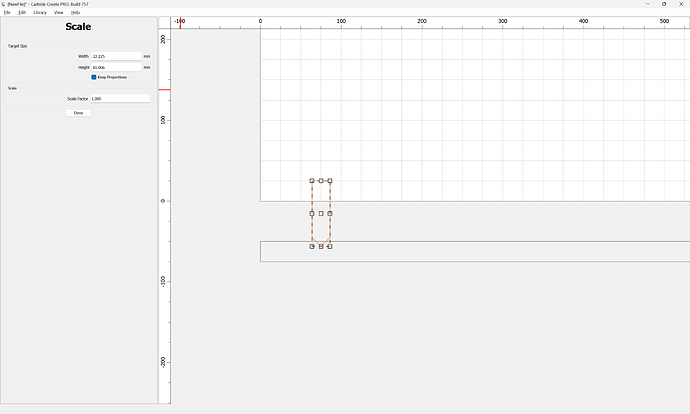

Draw up your tool in profile:

Draw a square from corner to corner of the tool:

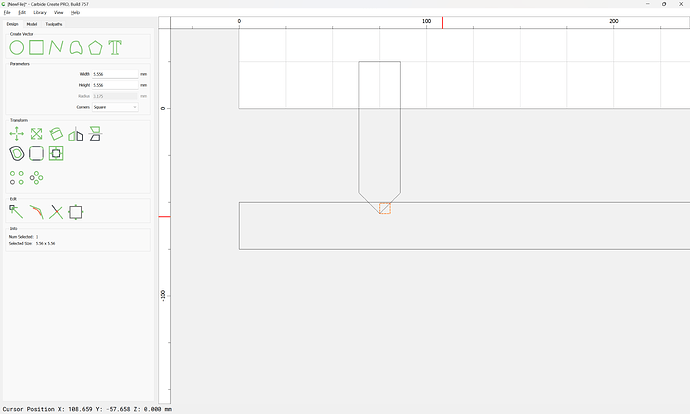

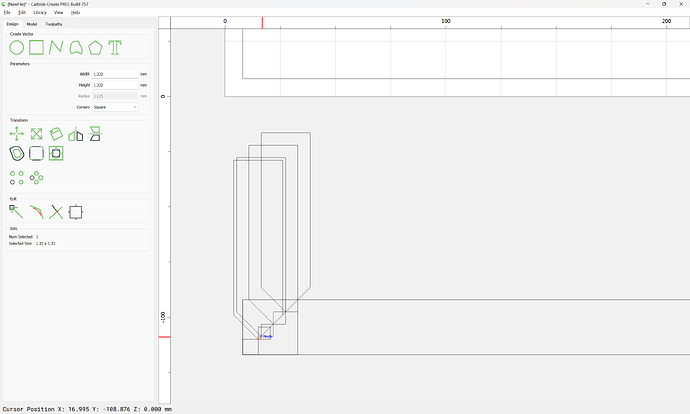

Reduce it in size to half:

Position it at the tip:

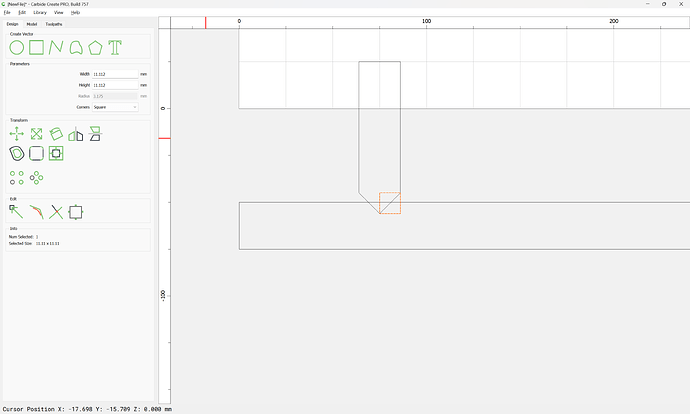

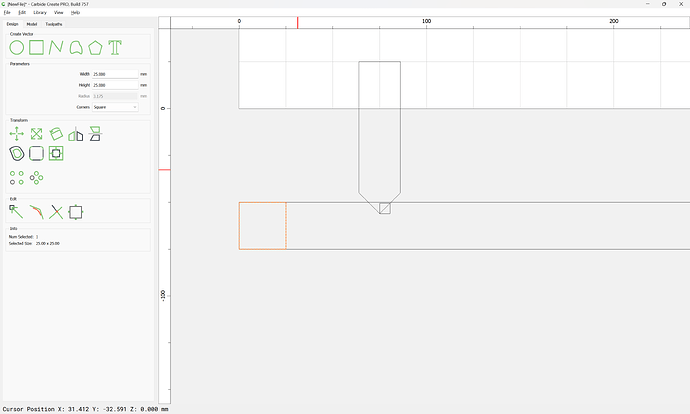

Draw a square at the corner of the stock:

Use the small square to position the tool at the top inner corner:

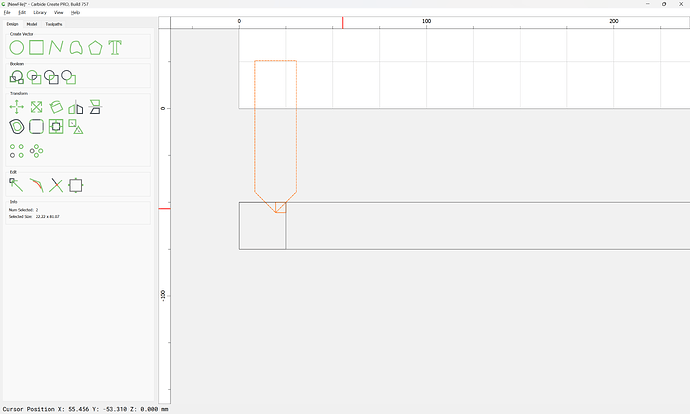

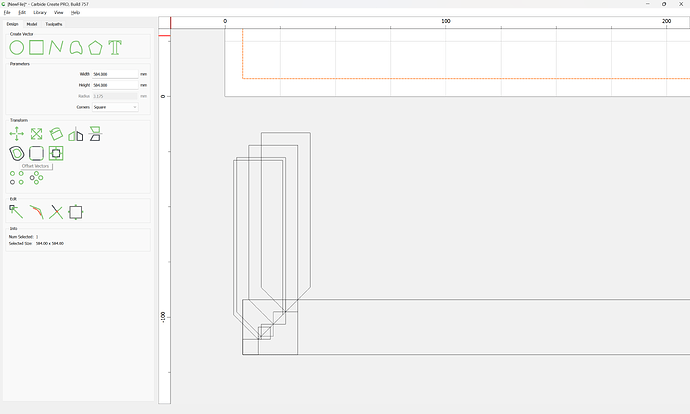

Duplicate it at a diagonal down to the deepest point which one wishes to cut:

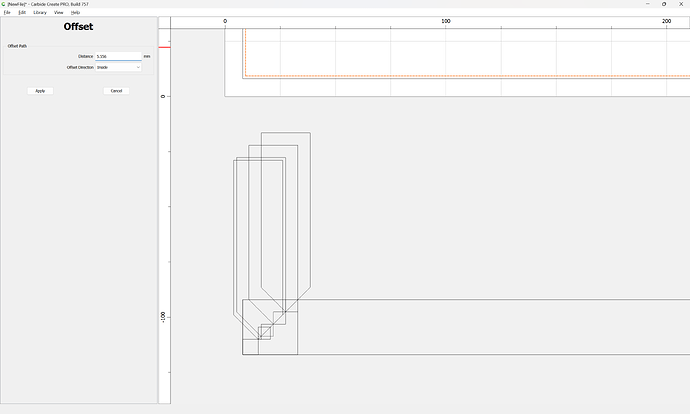

Then draw geometry at the requisite dimensions and assign no-offset Contour toolpaths to the requisite depths — easiest if one starts w/ the outside and works in:

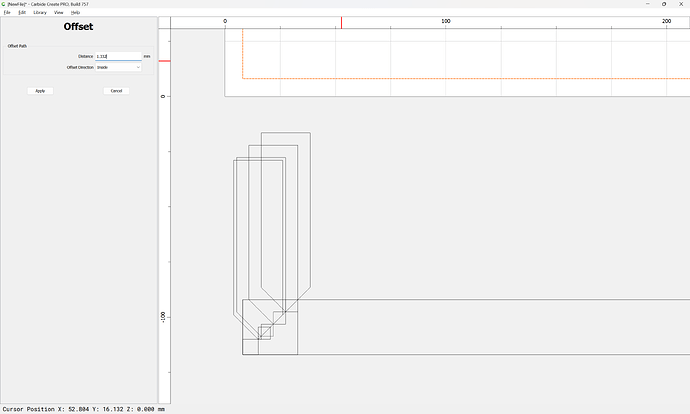

until one arrives at:

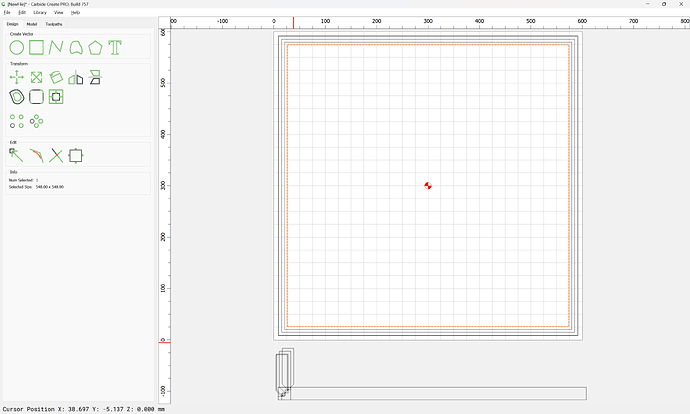

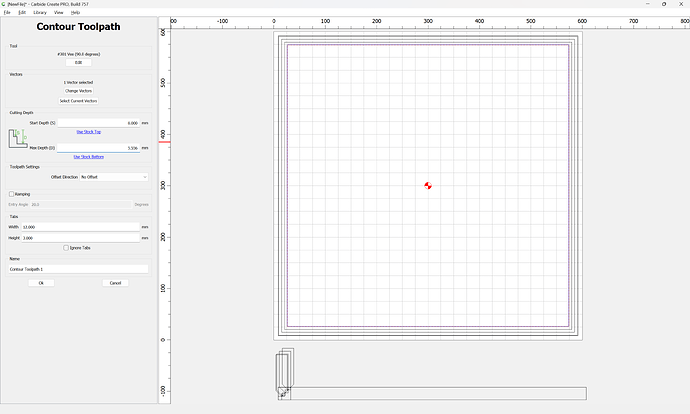

Then assign toolpaths, starting at the top and working down:

Lastly assign a pocket toolpath around the perimeter to cut the part out:

Probably it would be better to overcut the final V contour and let the square tool define where that edge is.

Increasing the size of the outer geometry makes things a bit clearer:

Attached as a V7 file:

45degree_edge_v7.c2d (72 KB)

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.