newfylukey

November 6, 2024, 5:15pm

1

Hello All,

I am using CC build 778 and having great difficulty getting inlays cut correctly. The issue seems to be on the plug side of things. The plug is constantly too small.

WillAdams

November 6, 2024, 5:32pm

2

Upload the pair of files you are having trouble with and photos showing the cutting results?

Are you using Carbide 3D tooling, or custom tooling? If the latter, screengrabs of your tooling definition and link to the product page?

newfylukey

November 6, 2024, 6:01pm

3

newfylukey

November 6, 2024, 6:07pm

4

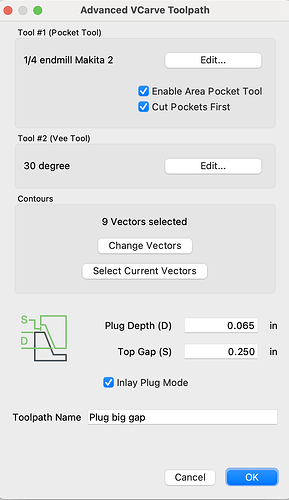

I have been playing with tthe settings and depths.

I did get one to fit. It is in the settings attached.

I programmed as a 30degree bit, but used a 15 degree bit to cut.

mhotchin

November 6, 2024, 9:27pm

5

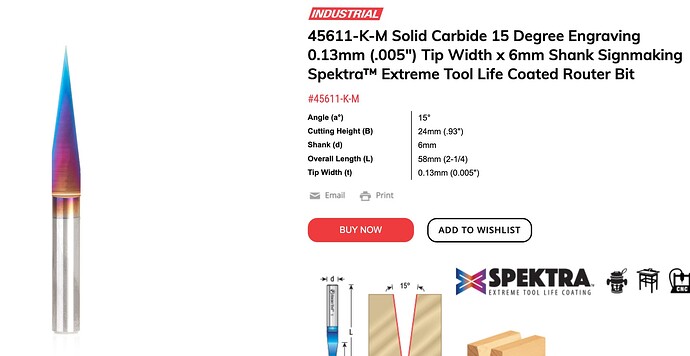

If you programmed as a 30, but used a 15, perhaps there’s a conflict of what the angle means?

A 15 deg half angle (measured from shaft to edge) is the same as a 30 deg included angle (measured edge to edge). CC uses included angle always.

1 Like

newfylukey

November 7, 2024, 12:58pm

6

I have the bits set up correctly as “included angle” (ie. a 60degree bit is put in as 60) ive had 2 carves fit perfectly when i half the bit angle. Im trying more today to see if the fit continues.

Tod1d

November 7, 2024, 3:31pm

7

Normally you would use the same tool, and set your plug depth to about .200, and top gap to around 0.050.

Can you show a picture of the tool you’re using? If the tip isn’t sharp the pocket will cut too big, and the plug will cut too small.

1 Like

newfylukey

November 7, 2024, 6:28pm

8

Hi Tod.

As you may have read, ive tried using the same bit multiple times with no success. Programming for a 30 and cutting using a 15 has been successful each time so far.

newfylukey

November 7, 2024, 6:30pm

9

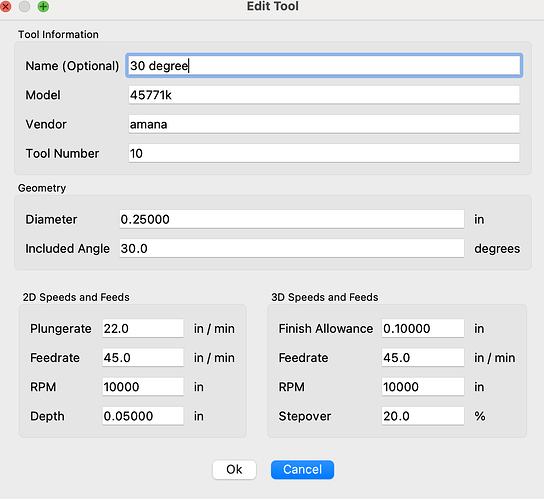

This is the 30 degree bit. Does anything there seem off to anyone?

WillAdams

November 7, 2024, 6:33pm

10

I would recommend using a #302 , 60 degree V endmill — the more acute angle means that the width variation as height/depth changes is less.

Tod1d

November 7, 2024, 6:39pm

11

I don’t think the angle of the bit is the problem. You should use the same bit for both sides, and for programming & cutting.

I meant an actual picture of the tool you are using on your machine. This was to verify the angle, and to make sure the point is actually “pointy”

system

December 6, 2024, 5:16pm

12

This topic was automatically closed after 30 days. New replies are no longer allowed.