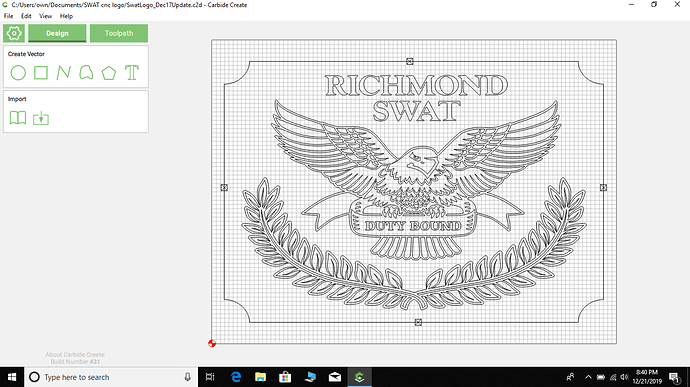

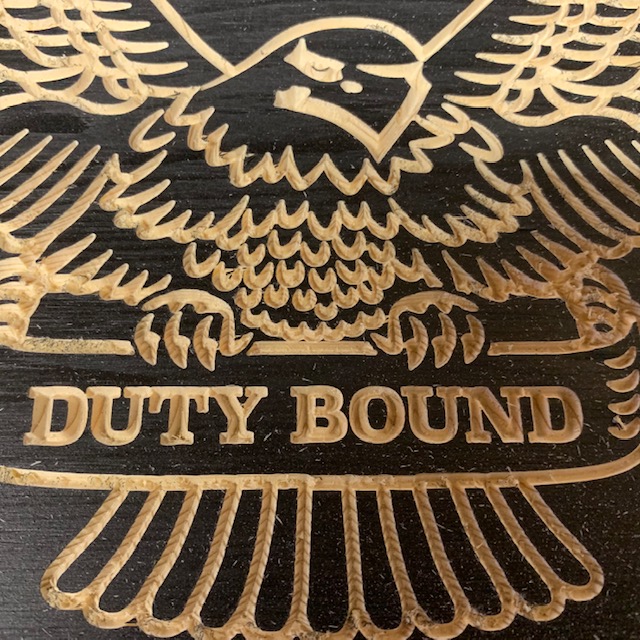

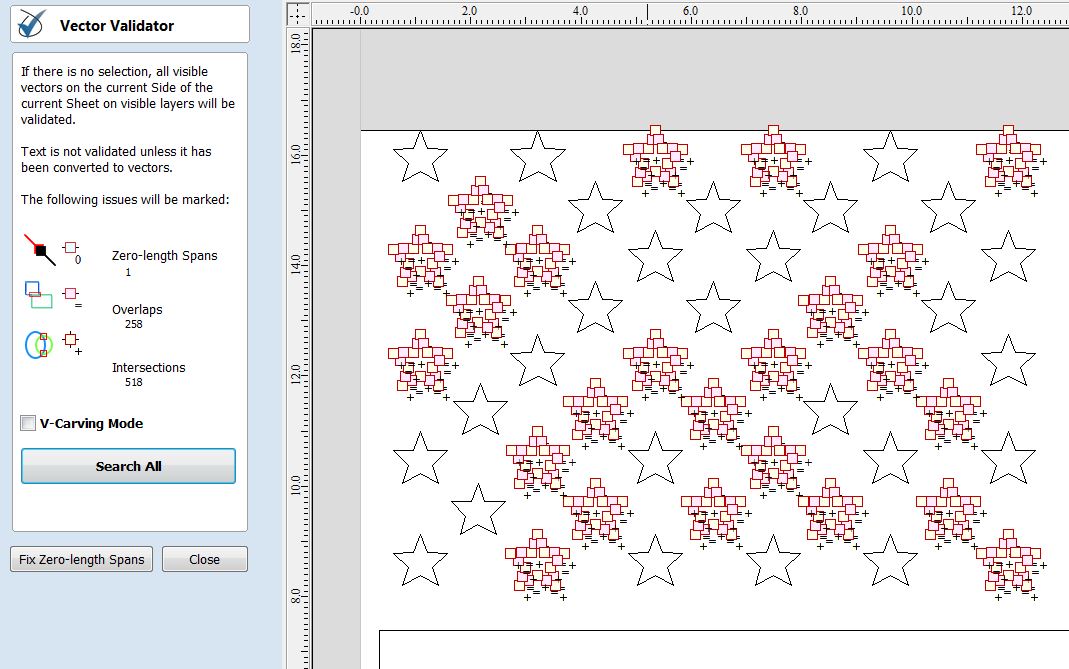

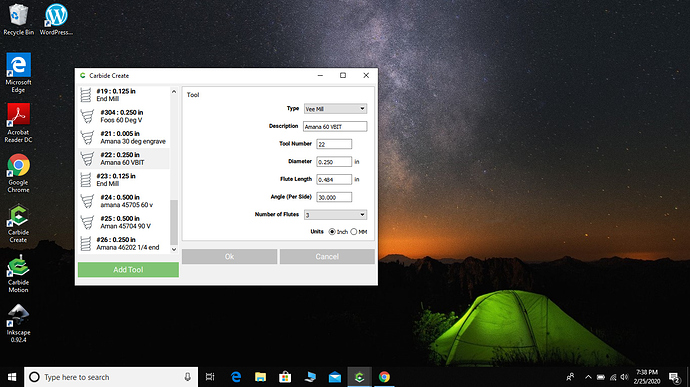

Hello all. I have a logo that I had redrawn by a graphics design person. I use inkscape to open it. I have entered it directly into carbide create. The logo is not drawn as single lines put as dual lines for all artwork. I assume they did this to allow it to vcarve? Here is the problem I am having. I first attempted to cut the logo, zeroed on top of my board with paper test, and right off the bat it is cutting too deep. So that leads me to believe it is because of the way it was drawn with the dual lines of everything. So, after wasting a lot of wood, I did paper test, then raised bit substantially and ran it and it turned out great. This was 2 months ago. I went to cut this same design again last night, thought I had learned my lesson, paper test, raised bit .55 mm above stock and set zero, started cut and boom, a wasted piece of wood, cut too deep. I probably needed to go up another .4-.5 mm to have been close to being right. So, is my problem with the way it has been drawn with these 2 lines, thus, based on how far apart they are the bit is trying to go deep enough to cut it? Am I going to have to have it redone again and make the space between lines smaller? Or will/can I have it redone with single line only? This is really frustrating me because I have a lot of requests for this piece and I am wasting a whole lot of time money and wood in 2 seconds every time I run it. I will add image shortly. Thanks everybody!