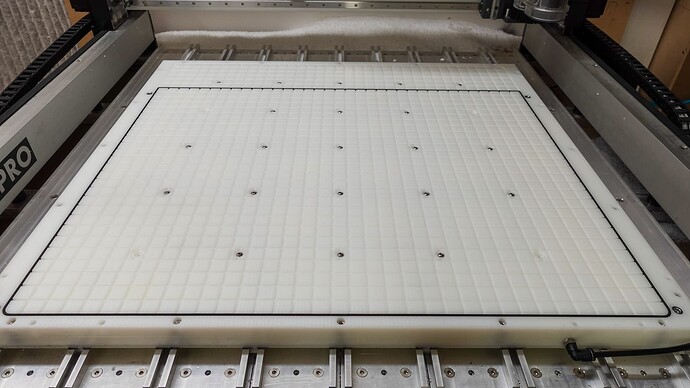

Made this from HDPE and using the Venturi components from Pierson Workholding. This thing has been a game changer for my work flow. I’ve put about 100 hours on it so far cutting plastics and a little aluminum. Have only done a little plywood and solid wood. The nature of it being Venturi does have its limitations when used with porous materials like plywood and hardwood and does not work at all on MDF without sealing (painting) the side touching the chuck. If you do production work on non-porous sheet goods I would 10/10 recommend.

We use the same venturi pumps for Nomad parts in our Brother machines. They’re great.

Would you mind sharing a bill of material?

I really like it! It appears you used 2 panels and cut the channels in between, correct? If so, what is the thickness of the panels (1/4 -3/8) and the size of the channels you cut? Are the venturi components what turn the compressed air into a vacuum? Sorry for all the questions, thanks for sharing.

I’m in Canada so I’ll have to break out the different currencies, also if you’re in Canada there will be extra tax, shipping and brokerage to consider. I had a full sheet of 3/4" HDPE which I paid about $420 CAD. The Pierson parts came to about $870 USD and then probably another $80 CAD for socket head screws, aluminum bar stock (used to clamp the vacuum chuck to the bed) and quality threaded inserts (Rampa brand). I also have a 1.5hp 15 gallon air compressor that has done well enough to keep up with the air demands.

Thanks Tim! I used two 3/4 HDPE panels to start with and they got milled down to about 0.7" each during the fabrication, so about 1.4" total thickness. The channels between the two layers and the channels on the top are all 0.1" deep. Pierson Workholding has many informative videos that informed much of this design. And yes you’re exactly right, the Venturi components are what make your compressed air able to pull a vacuum.

When Ken asked for a “Bill of Material”, I believe what he intended was a “List of Materials”. A bill of material is commonly found on shop drawings, listing the material, and quantities of a project.

Thanks Steve that went right over my head ![]()

Pierson Workholding Parts:

SmartVac 3 Vacuum Port Screws - 10 pack x 3pc

SmartVac 3 “Gasket Slot” Endmill for 1/8 Gasket x 1pc

1/8" SmartVac 3 Vacuum Gasket (50’) x 1pc

SmartVac 3 Connection Kit x 1pc

SmartVac 3 Vacuum Power Unit x 1pc

Other:

3/4 HDPE, 33" x 30", 2pc

Rampa SKD330 inserts, 20pc

Socket Head Screws

0.625" x 0.25" x 30" Aluminium 6061 Bar Stock x 6pc

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.