While working on learning to cut dovetails vertically, I’ve discovered that I can’t describe my material thinner than 1 inch. the simulation shows a tail pocket, what am I doing wrong? So many questions…!

Which software are you using?

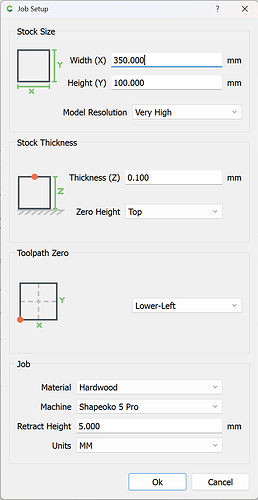

Carbide Create allows as thin as 0.1mm:

For doing this, see:

and:

That said, why?

They’re easily done by hand:

but on a CNC require a minimum of 3 setups:

- cut parts to size/length, machine any internal features

- clamp four boards on the machine, two flat, two vertical and cut joints at two corners

- rotate boards (maintaining the correct orientation) and cut the other two corners

Far easier to use a joint such as a full-blind miter box-joint:

which allows cutting a ready for joinery part in a single operation.

Since he’s talking about ‘vertical cut’, doesn’t that mean he has the board held vertically at the front of the machine?

In that case, the ‘thickness’ is the Y dimension, and CC for some reason has a lower limit of 25mm on that axis.

You are correct, but usually thinness refers to Stock Thickness.

That said, it is incorrect to say that the Y-axis/Stock Height cannot be set to less than 1 inch, since the min. is 25mm.

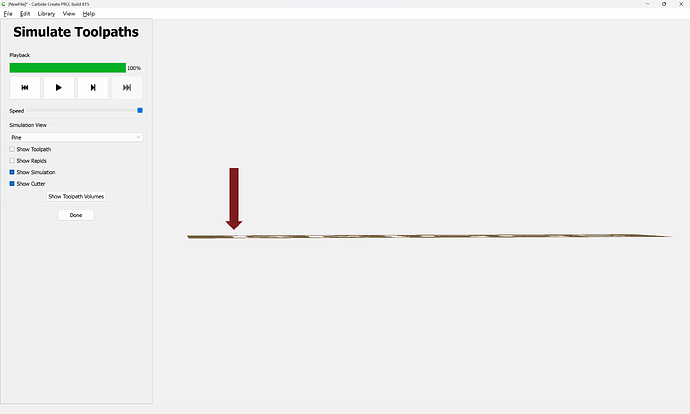

Moreover, one cannot get an accurate preview of how a dovetail tool will cut, so one has to take this on faith — just set the cut to match the actual thickness of the board(s).

yes, the boards are clamped perpendicular to the bed, and was looking down at the end grain, and yes, to me, the Y direction was thickness. Will informed me that Y under 25mm is undefined.

That was actually good to know, because up until then, I was spending a lot time trying to figure what I was doing wrong. I then enlarged the dovetail cutter shape to extend beyond the 25mm limitation and tried cutting. What I got was what approximated a dovetail, sort of!

I will try to attach the file so you can see the results, but man, needs a lot of work! Once I got over the 25mm diversion it started to be fun!

A further consideration is that one might as well clamp 2 (or 4) boards at a time, which markedly increases the area which one needs to cut, so the min. stock size is even less of a consideration.

When onto the cutting, z is cutting depth, but the confusing part is the Y limit in this instance. What part am I getting confused about? How do I portray the cutter dimensions, or is that even necessary? You’re right though stacking the side boards and cutting them, and then stacking and cutting end boards would be efficient. Once I’ve learned how to create the best fitting dovetail joints, because that makes perfect sense.

Thank you

This topic was automatically closed after 30 days. New replies are no longer allowed.