Which software are you using?

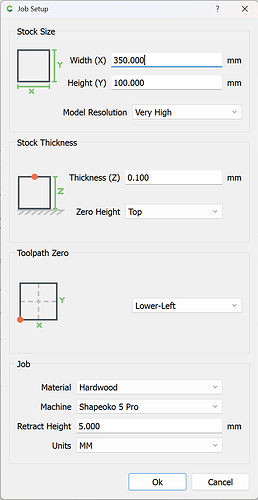

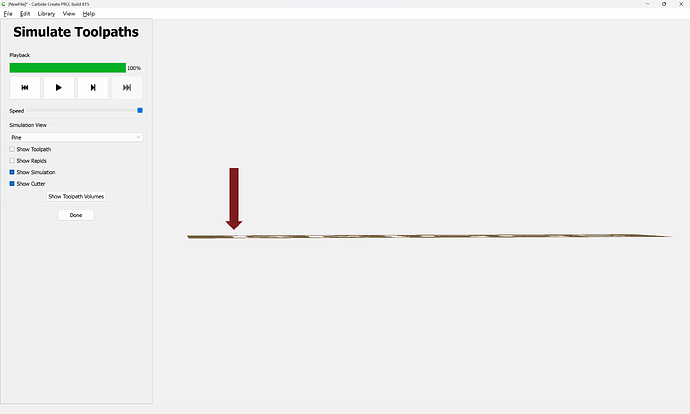

Carbide Create allows as thin as 0.1mm:

For doing this, see:

and:

That said, why?

They’re easily done by hand:

but on a CNC require a minimum of 3 setups:

- cut parts to size/length, machine any internal features

- clamp four boards on the machine, two flat, two vertical and cut joints at two corners

- rotate boards (maintaining the correct orientation) and cut the other two corners

Far easier to use a joint such as a full-blind miter box-joint:

which allows cutting a ready for joinery part in a single operation.