Hi Guys

I’m not sure if this is an issue with Grbl, Carbide Motion, dmap2gcode, or user error, so bear with me. Knowing me, this is something simple that my typical overthinking has caused me to be blind to. I am using a newly built Shapeoko XXL.

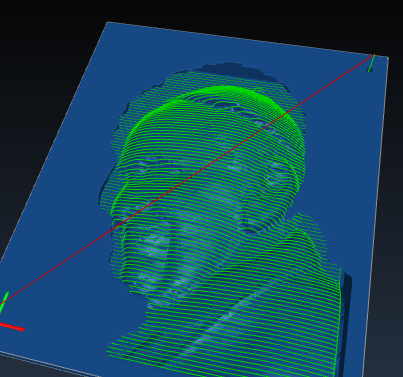

I used dmap2gcode to generate two milling operations: a roughing pass and a finish pass. The roughing pass worked beautifully with a 1/4" end mill running feed at 50mm/min and plunge at 25mm/min. It wasn’t nearly aggressive enough for a rough pass, but it worked overall, so I didn’t kill it.

Now, when I went to run the finish pass, the feed rate was incredibly slow. It didn’t matter what I entered for the feed or plunge in dmap2gcode, the XXL would move at the exact same rate. If I exported new code with different values like a lower Z-Safe, that is respected, but it would still crawl for all moves. The exception is rapids, which it has no problem with. I’ve cranked the feed up to a ridiculous 4000mm/min with no change, and I’ve checked the max feed in Grbl which is set to 5000mm/min.

Can anyone shed some light on this? Here are links to the two nc files, as well as my Grbl settings:

Rough: https://drive.google.com/open?id=0B4QPvDHcUA-daHQwU1g4cjlEajA

Finish: https://drive.google.com/open?id=0B4QPvDHcUA-dODUtRVprNTdvbU0

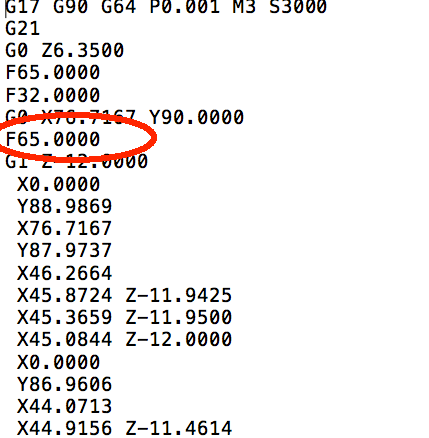

$0=10 (step pulse, usec)

$1=255 (step idle delay, msec)

$2=0 (step port invert mask:00000000)

$3=6 (dir port invert mask:00000110)

$4=0 (step enable invert, bool)

$5=0 (limit pins invert, bool)

$6=0 (probe pin invert, bool)

$10=255 (status report mask:11111111)

$11=0.020 (junction deviation, mm)

$12=0.010 (arc tolerance, mm)

$13=0 (report inches, bool)

$14=1 (auto start, bool)

$20=0 (soft limits, bool)

$21=1 (hard limits, bool)

$22=1 (homing cycle, bool)

$23=0 (homing dir invert mask:00000000)

$24=100.000 (homing feed, mm/min)

$25=1000.000 (homing seek, mm/min)

$26=25 (homing debounce, msec)

$27=5.000 (homing pull-off, mm)

$100=40.000 (x, step/mm)

$101=40.000 (y, step/mm)

$102=40.000 (z, step/mm)

$110=5000.000 (x max rate, mm/min)

$111=5000.000 (y max rate, mm/min)

$112=5000.000 (z max rate, mm/min)

$120=400.000 (x accel, mm/sec^2)

$121=400.000 (y accel, mm/sec^2)

$122=400.000 (z accel, mm/sec^2)

$130=425.000 (x max travel, mm)

$131=465.000 (y max travel, mm)

$132=80.000 (z max travel, mm)

ok

EDIT: I’ll also mention that I never see the velocity in Carbide Motion exceed 100mm except during rapids. Don’t know if that’s related…

Thanks!