Hello Friends, and Happy Sunday!

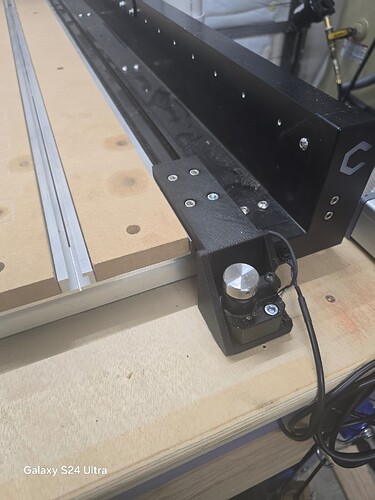

Longtime SO4/compact router user, but just upgraded to the SO5 Pro and 65mm VFD.

I have two questions related to the VFD/Dust boot/tool changes:

Question #1:

In the past, with my SO4, when I had a tool change in the middle of a job, when prompted to “Insert the next tool”, I would remove the magnetic Sweepy dust boot bottom, swap the tool, press confim, and then the bitsetter would do it’s thing. The router would return to the position just to the left of the bitsetter, and prompt me to set the RPM on the router. THIS is when I would replace the dust boot bottom, Confirm, and then… happy days, the machine goes on and cuts.

So, my question is now with the VFD Spindle on the SO5, once I change the tool, the machine goes to the bitsetter, measures, and then the Spindle starts and it goes to cut - how do I “pause” it to replace the dustboot???

I of course tried the “Pause” command in Carbide Motion, but that only pauses the CNC, not the Spindle. What is your workflow for this?

Do you actually turn off the VFD Spindle? I was worried that doing so would cause some sort of a disconnect and it wouldn’t resume when i turned it back on.

Does the “Feedhold” button on the power pendant on the SO5 pause the machine AND the VFD? If so, do you use that when you need to replace the dust boot?

Is there some other way in Carbide Motion to get it to pause after the tool change, but before resuming the cut so I can get the dust boot back on?

Question #2

Also, on a related topic… When you change the tool when using the VFD Spindle, do you actually turn off the VFD Spindle Control box? And if so, do you press the red power button on the VFD controller to do so, or do you just kill the power to the outlet it’s plugged into. I assume both approaches are essentially the same. (My VFD control box is on the back of my table, plugged into a switched outlet and the switch is on the front panel of the table - again, worked great with the compact router.) Of course, Carbide Motion has stopped the spindle, but I felt a lot safer changing the tool on the compact router, because I could kill the power to it.

Thanks in advance!!

~ Mike