A real power meter is actually better (more accurate) anyway since it should correct for power factor. I was unable to find a housed COTS plug-in version, so I had to hack together plug-in cables and housings for my COTS router power monitor modules. Care to share what power meter you have?

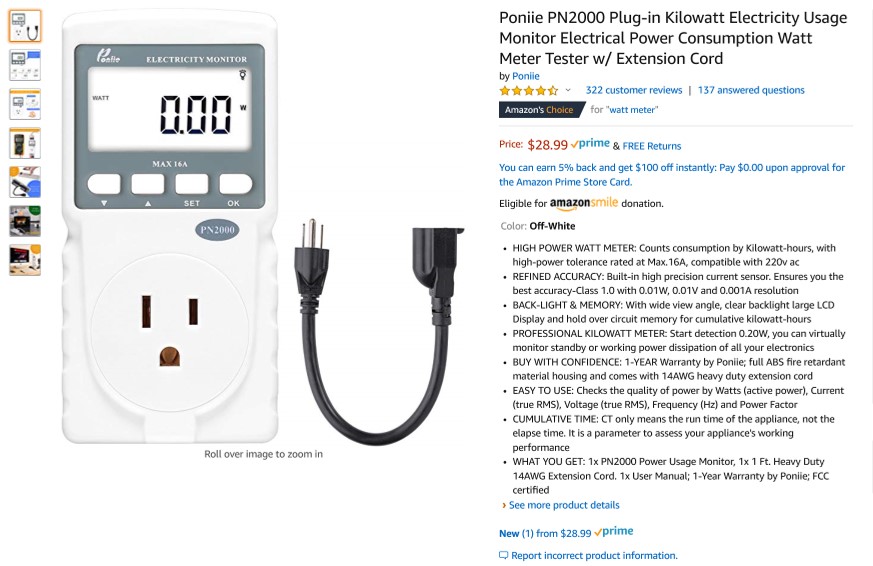

Edit 0924 PST: I looked again and found a COTS power meter that sounds like it should work. I’ll compare it with my others for accuracy and response time with some routers.