Or maybe it’s just a software/firmware issue in the VFD - since he and Piotr are apparently using manual RPM control (and started from factory settings)!

So, I finally tested that PD0054=1 and monitoring the voltage between VO and ACM, and…was disappointed to see that it gives me similar results as what shows up on the display. I read 0.75V after a 5min warmup of the spindle, while the display was reading 1.6A. After beginning the test cut (1/4" 3 flute for 1/4" DOC pocketing in MDF @ 180ipm and 20000RPM), the value did not change…at all.

And while not cutting, once the spindle warm-up is done, the Amps are the same whether I’m at 5000 or 24000RPM. Hopefully someone else with a Huanyang VFD could confirm whether they do see the “Axxxxx” readout change during cuts ?

I will hook up my Huanyang VFD during the weekend and test the same. I’m currently using a Omron VFD, but I have the Huanyang that came with the spindle in a box.

Tested on my both VFD’s and no changes at all

Mmh, it’s not only me then. Shoot…

@Julien, others. The VFD needs to sense motor current to keep from exceeding the motor’s rated current. The problem seems to be associated with the output/display of it. Maybe the VFD “assumes” that when remotely controlled (like everyone here?) it disables output/display updates. Are other parameters (RPM, frequency, voltage, etc.) properly output/displayed?

As far as I can tell RPM/frequency/voltage are correctly displayed. It is quite possible that “remote” control does this indeed (though there is no indication of that behavior anywhere in the manual)

Man, Julien, the resources you provide for everybody on this forum are excellent. Especially for those of us that love our Shapeoko’s but aren’t so technically savvy. I’ve upgraded to the same setup but with the 110V 2.2KW spindle and just wanted to check with you to see what parameters you would change for the 110v version? PD141 and PD142? Would the poles of mine also be 2? Thanks!

yes PD141 would be 110 (I suppose if you bought the VFD in a kit along with the spindle, they may already have programmed it that way)

PD142 is for the max rated current, the value should be available on your spindle

The number of poles is a spec of the spindle, if you don’t have the information available it’s probably 2 pole if the documentation states a max frequency of 400Hz, and 4 if it is 800Hz

The safest would be to consult with the guys here on the forum who use a 110V spindle and a Huanyang VFD, to double-check their settings. @Griff, @wb9tpg and others should be able to confirm?

My spindle is 220v but I can check the parameter tomorrow

Does the fact that US and EU frequencies differ affect is any way the parameters or their calculations?

It seems to me that only PD144 would be impacted, but someone from the US who installed this VFD could confirm.

mine came with a fancy printed instruction book;

pd144 says

Set Range: 0 - 9999 Unit 1r/min factory setting: 1440

This is set according to the actual revolution of the motor The displayed value is the same as this set value. It can be used as a monitoring parameter, which is convenient to the user. This set value corresponds to the revolution at 50 Hz

I can’t quite remember how mine was mapped, but I kept having grounding issues. GRBL would stop for no reason half way through a toolpath. I earthed everything, but was still having issues. Then I opened that connecter at the top of my spindle. Ground pin was not connected to anything!

I connected it to the spindle housing. Not had a problem since.

So with a Chinese spindle it’s probably good practice to check the wiring!

That is disturbingly common on the Chinese spindles, I would check the earth before even thinking about powering them up.

Apart from that, it has been excellent. Inexpensive, but good! I would never go back to a noisy brushed trim router!

I too have opted for a spindle, helped over the line by G-Penny/AliExpress doing a -17% Black Friday offer for spindle and VFD combined.

Having got over my ‘more power = better’ cravings, I opted for the 800W/220V/65mm/ER11 model with the ‘mini’ 1.5KW VFD.

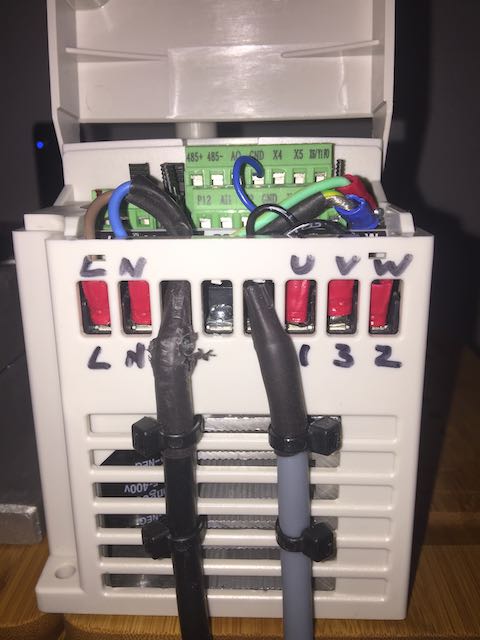

Having read @Julien’s notes above, I was interested in what differences the ‘mini’ version of the VFD would bring. The first thing to note is that I correctly (double-checked) wired connector pin 1 to ‘U’ on the VFD, pin 2 to V, pin 3 to W and pin 4 to Earth + cable braid, and got reverse rotation. I swapped 2 and 3 and now see correct rotation. I want to read up on this just to be 100% sure I haven’t got phases competing with each other for having done this, but it would appear not.

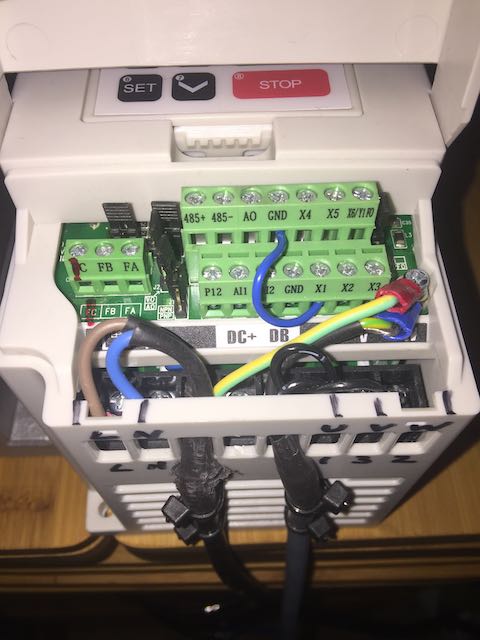

The small VFD didn’t need the jumper VI setting as the out-of-the-box settings (soft and jumper) were correct. Just needed to install the ‘Forward X1 to GND’ jumper, as also shown above.

Worked through all of the PDxxx settings described above (in the mini these are Fxxx settings), and read the manual front to back, then back to front to be sure I agreed with them all. Left F001 and F002 as Keyboard and Potentiometer control, then successfully started up the spindle at 5hz for 1 min just to confirm a) direction of spin, and b) proper function - keeping in mind that I haven’t yet hooked up the coolant.

Next step is mounting the HDZ 65mm clamp (from Carbide, not the G-Penny clamp) on my HDZ 3XL, hooking up the coolant and water flow indicators, water temperature display and then go through the ‘start it slowly and let the bearing grease sort itself out’ routine.

thanks for reporting, it will be quite useful since people buying now will likely get that new VFD series.

I created a small “5min warmup” macro that executes a series of M3S[xxx] following by G4P30.0, with xxx from 500 to 24000 in steps of ~1000, giving it 30 seconds per step. I found it to be a good compromise (long enough that it really is a warm-up, and short enough that I won’t be tempted to skip it when I am in a hurry). I run it a single time at the beginning of each session in the shop. It may or may not be strictly required, but it can’t hurt my bearing’s life and precision.

You did the right thing, one definining characteristic of a three phase motor is that if you invert any two connections it will spin the other way, this applies to BLDC motors too.

I don’t have a tachometer with which to measure spindle speed vs GRBL request. Any real-world tricks that anyone has found to be successful? I tried the Gates app, but the sound is too ‘noisy’ for it to focus on the fundamental frequency.