I too have opted for a spindle, helped over the line by G-Penny/AliExpress doing a -17% Black Friday offer for spindle and VFD combined.

Having got over my ‘more power = better’ cravings, I opted for the 800W/220V/65mm/ER11 model with the ‘mini’ 1.5KW VFD.

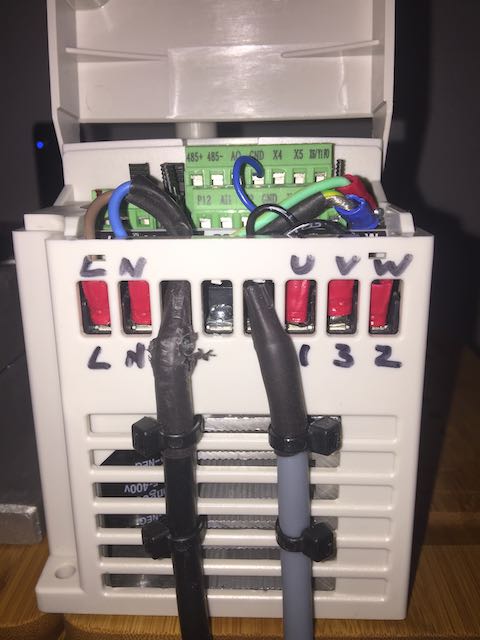

Having read @Julien’s notes above, I was interested in what differences the ‘mini’ version of the VFD would bring. The first thing to note is that I correctly (double-checked) wired connector pin 1 to ‘U’ on the VFD, pin 2 to V, pin 3 to W and pin 4 to Earth + cable braid, and got reverse rotation. I swapped 2 and 3 and now see correct rotation. I want to read up on this just to be 100% sure I haven’t got phases competing with each other for having done this, but it would appear not.

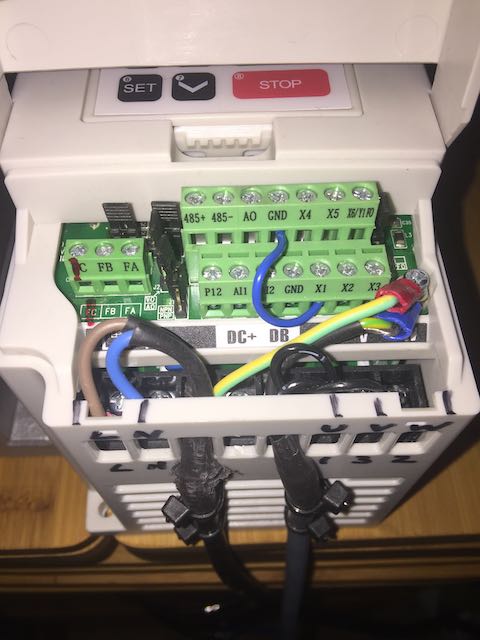

The small VFD didn’t need the jumper VI setting as the out-of-the-box settings (soft and jumper) were correct. Just needed to install the ‘Forward X1 to GND’ jumper, as also shown above.

Worked through all of the PDxxx settings described above (in the mini these are Fxxx settings), and read the manual front to back, then back to front to be sure I agreed with them all. Left F001 and F002 as Keyboard and Potentiometer control, then successfully started up the spindle at 5hz for 1 min just to confirm a) direction of spin, and b) proper function - keeping in mind that I haven’t yet hooked up the coolant.

Next step is mounting the HDZ 65mm clamp (from Carbide, not the G-Penny clamp) on my HDZ 3XL, hooking up the coolant and water flow indicators, water temperature display and then go through the ‘start it slowly and let the bearing grease sort itself out’ routine.