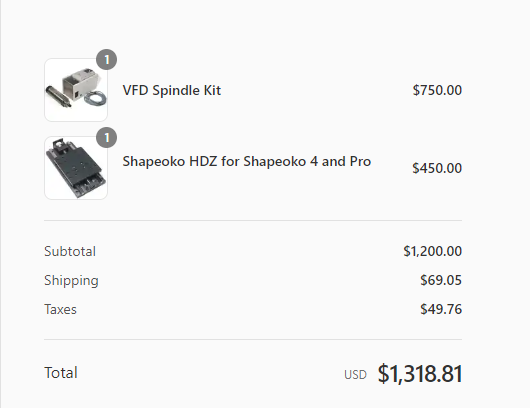

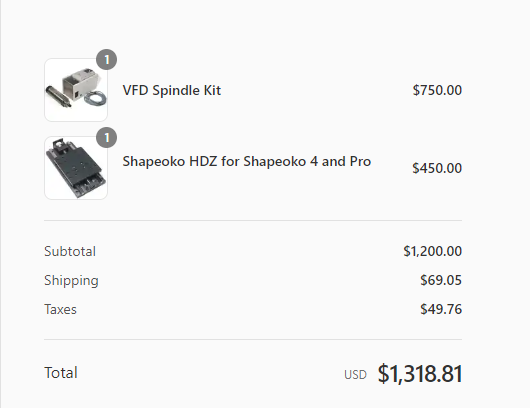

Super excited to see the VFD Spindle Kit back in stock! Just ordered mine. Can’t wait to retire the Compact Router, dang thing is still chugging after 2 years of everyday use!

Can’t wait to get this installed!

Super excited to see the VFD Spindle Kit back in stock! Just ordered mine. Can’t wait to retire the Compact Router, dang thing is still chugging after 2 years of everyday use!

Can’t wait to get this installed!

Is there an instruction manual for the VFD?

Everything is installed and double checked. Followed the YouTube video’s to a tee and sent the software change to the controller. When I turn the VFD on, everything comes on with a blinking 0.0 and FWD and Hz are solid red.

When I send the M3S10000, it trips my GFCI outlet every time. I’m stuck here ![]()

Only thing plugged in are the 2 led lights, machine, and VFD.

Any info or suggestions?

If you haven’t yet, send an e-mail in to support and we’ll work to resolve. I don’t believe a manual has been posted as of yet, but I’ll check.

Spending the night doing research, which I can say…being in this time and space of technology and information, it’s amazing just how much stuff is at our fingertips.

From what I gathered, standard VFDs, when powered from GFCI outlets, can cause the GFCI to trip due to the leakage currents generated from the high switching frequency of the VFD’s power devices and the harmonics associated with them .

The answer is short and simple: GFIs suck. The best ones don’t suck as much, but they all suck.

Luckily I can test this theory, as I have a non GFCI outlet somewhat next to the machine, but it’s definitely not ideal to run the power over. I also have some serious power outlet issues throughout my entire garage with my associated machines, and I can’t change any of it as I’m on a military installation leasing the space ![]() .

.

Also, I don’t fully understand how to set the RPM of the spindle, as I usually default everything to 18,000. Any info if this is set by the software?

I’ll have to test first thing in the morning and get creative with my power requirements. I spent the night out of the garage and took the wife out to eat. Best to start fresh in the morning and find the solution. Tomorrow is a new day.

It’s taken care of by the gcode and the controller for you: the gcode has M3Sxxxx commands where xxxx is the RPM for that particular toolpath, the controller picks up that value and modulates the average output voltage on the PWM signal to the VFD, which in turn converts that voltage to the desired RPM on the spindle. It’s automagic, and it’s one of the benefits of having a VFD and spindle, enjoy ![]()

That’s my understanding too. Just curious how Fusion360 with send it when I post the process. I might play around with the settings and experiment with it

phew, well thanks to your experience I will avoid the ‘stock’ outlets in my garage shop to the ones I installed. What with all this ArcFautl and GFCI breakers, I have enough trouble with Ham Radio.

The RPM value you set in each toolpath in F360 will be transformed by the post processor into into a M3Sxxx command in the output file, that’s really all there is to it.

Thanks @Julien !!!

I’m on the deck drinking coffee…getting ready to start the day in the garage.

I have 10 satellite ![]() plaques to make today, and going to make another video of it. Exciting times

plaques to make today, and going to make another video of it. Exciting times ![]()

By the way, I don’t know which post processor you are using but make sure it has the ability to add a delay after the spindle start command, it takes a few seconds for spindles to ramp up to target speed and plunging into the stock while the endmill is not spinning yet is no fun ![]()

Did some electrical budget analyst and re-ran a ton of stuff.

Turned everything on, sent the command and works! I can’t believe the noise difference of the spindle vs the router. The spindle is super quite!!!

Thanks all!

@Julien is there a way to update the Carbide3D.cps in Fusion360 to generate the g-code with dwell time for the spindle. It’s not built into yet as an option.

I ended up using opensbuilds CNC:grbl post processing that had this option included and set it to 4 secs to let the spindle get to 18,000 rpm’s before it plunged. I did a test run and no issues with the code.

Just would like to keep everything within carbide without loosing Fusion

I’m not sure who owns/maintains the carbide3d.cps post actually…

I use @neilferreri’s post which does have the spindle delay param, and as long as Neil is around it’s probably the de facto “supported” post for C3D machines ![]()

This topic was automatically closed after 30 days. New replies are no longer allowed.