I purchased the Shapeoko 5 PRO on April 16, received it fast, and assembled it. I also built a folding table for it. At the time, the Spindle hadn’t arrived yet - it arrived two weeks later. Since then, I haven`t had any time to play with the machine, and today I finally assembled the VFD Spindle and tried to make my first cut.

Issues :

Carbide motion frequently " not responding" version 649

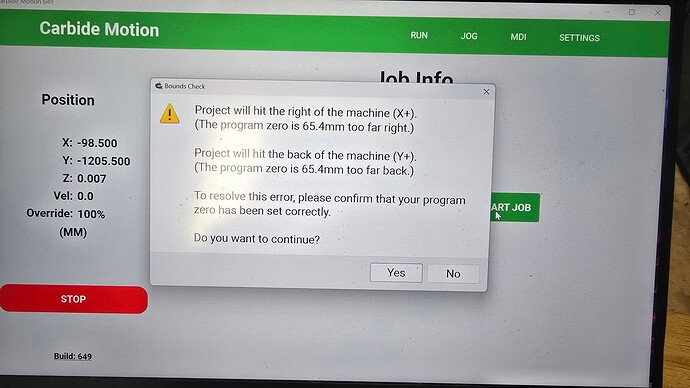

I made a simple circle file for wood cutting in Carbide Create ( free version) with a depth of 3mm and bit #201 1/4 shank. When I try to start a job says: The project will hit the right side of the machine. The program zero is 309.mm, or if I change the position of the wood piece in the program when creating the file, it changes these values, but still warns will hit some of the sides

If I bypass this warning, the machine starts and always goes to the right back corner, although I set it up front, left, or center. The spindle is sitting too high, but still simulates making a circular motion

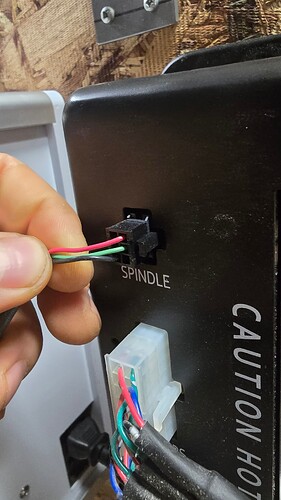

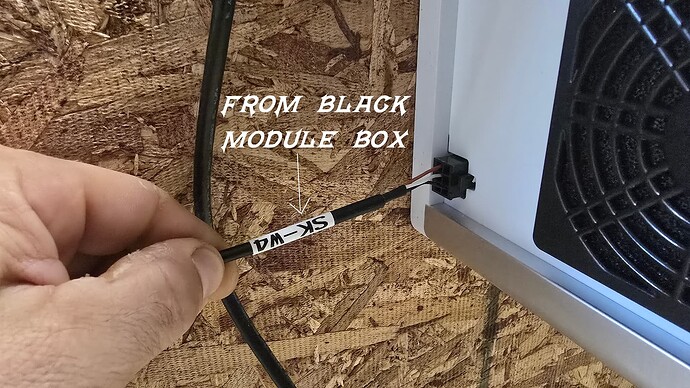

The VFD Spindle is not spinning at all - not in a task, not in a warmup test, the button is pressed, and the red ring around is light on, just 2 flashing 0.0 on the red display of the VFD module

And last, when the machine initialized the home or zero-s, I don`t know what, moving just fine

Or randomly left, right, center, or any corner in the test page, but when I load a task and start going to the right back corner, it vibrates as if it’s not a proper square or aligned if it’s not a task, same patch, but not vibrations.