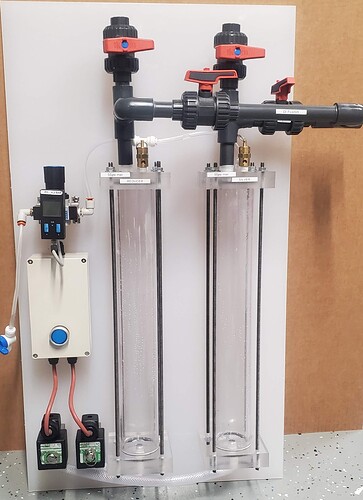

Fully fabricated on a 4 Pro and a 3 XXL. This is a Silvering station for Vinyl lacquer masters(Used to make vinyl records), we clean them and then spray silver nitrate and reducer on them to create an ultra thin layer of silver. This makes the Lacquer master of a vinyl LP conductive so we can electroform nickel to make an inverted copy of it. That inverted copy is de-silvered, back sanded, formed and used in a vinyl press to make records. Most of the White polypropylene is table saw cut then processed on the Shapeoko, then welded using PP welding rod. The pressurized vessels have a 3/4" polycarbonate end blocks that are cut on the Shapeoko and tapped NPT.

. Control box cutouts are also cut on the Shapeoko.