Using the LMT Onsurd Bit.

Visually, the only difference I can see in the geometries of the LMT vs Amana bit is the LMT is a bit “flatter” at the tip where the Amana comes to more of a point. So I wasn’t expecting MUCH difference but the LMT did produce some interesting differences.

In fairness, I was cutting much more curved shapes this time around, but in short the conclusions that I’m drawing are:

- Finishing results on both bits are almost identical with the top half of the of the 1.5" cut being pretty consistent but then loosing it >.75" down, with the LMT producing less of a Mirror finish.

- Roughing results on the LMT were more visually acceptable, but not smoother. When the Amana roughed it attempted to polish the cut more then the LMT does so the end result was a visual juxtaposition in black that is very noticable. However, when the LMT roughed the cut was more matte all the way through pretty much to the point where it looks uniform enough from a distance.

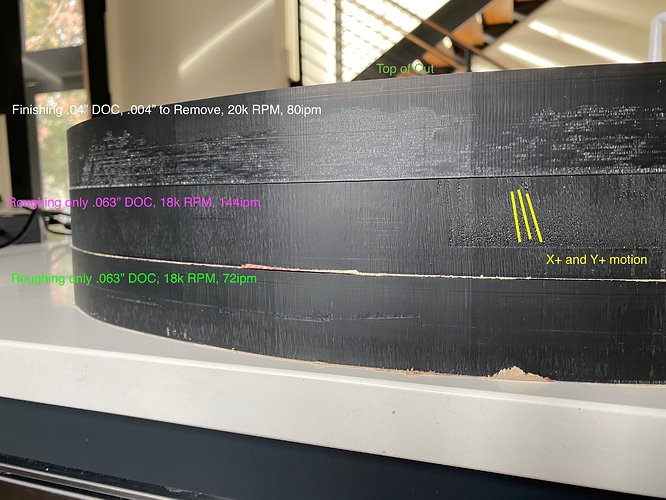

The LMT also produces more audible chatter to combat that I tried various combinations of RPM and feed rate. Results pictured below.