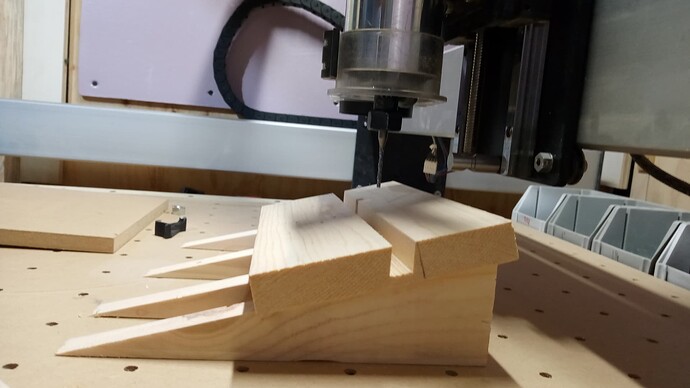

Ok, so far, all I’ve done is cut some wood angled pieces to 15 degrees…but after I did that I said to myself, “Great! now how in the hell are you going to actually hold the project to these 15 degree pieces?” lol. Has anyone ever tried this before on their Shapeoko? Does anyone have any pictures of their jig they could share for inspiration? All I have at this point are 4 15 degree triangle shaped pieces of wood…literally but I feel if I could maybe put those pieces on a platform piece, that could then be secured to my threaded wasteboard, that would get them held down, but I just dont know how I would keep a piece of wood secured to the 15 degree pieces. Any help or ideas would be appreciated. Thanks

Could you post photos of the parts in question?

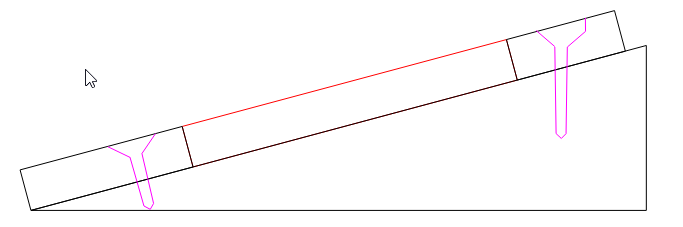

Also, a diagram indicating what orientation the dados need to be cut at?

The way I would approach this is to make a fixture to hold the wood in the necessary orientation.

How will they ultimately be used/assembled? Loose tenons?

That piece of wood was cut on a table saw, but I’m just using it for the example of showing you

You could put screw holes in the wedges & bolt them down to the table.

If you can live with holes in the workpiece, screw it to the wedges.

If not, you could 2-way tape (or painters tape & glue) it

Or you could screw through the bottom of the wedge into the workpiece without breaking through the top.

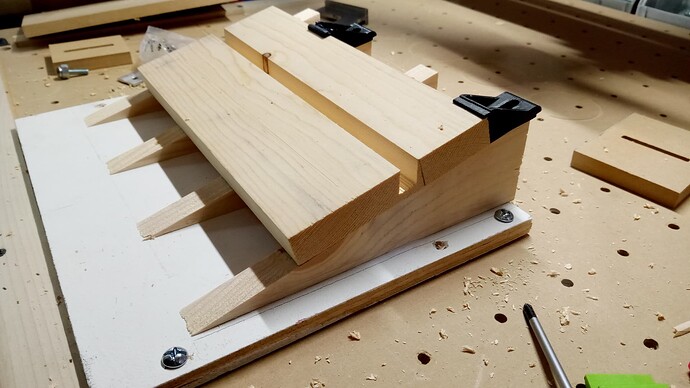

You could also use tie down clamps screwed into the wedges. You may need to move the workpiece further down the wedge so you have room to clamp both top & bottom.

If you’re going to do a bunch of these, you could attach 2 horizontal boards to the wedges. The bottom one permanent, and the top one you’ll loosen & tighten to clamp your workpiece.

If you make the space between them just a hair smaller than the width of your workpiece, the angled screw in the top board will pull the board down & pinch the workpiece when you tighten the screws.

woooo wee! thats sweet i like that. will send a pic in a few of what I’ve done so far. Thanks though

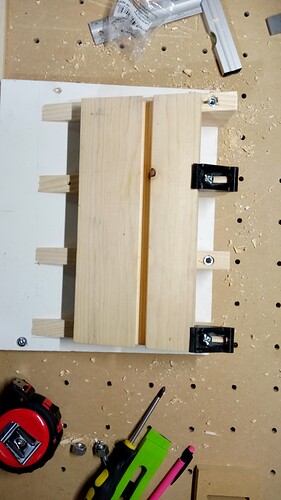

Ok, so …I think I will look at this as a prototype lol and will more than likely redo this in a better way before trying to actually use it, but for now, to get my point across, this should help yall see where I went.

I added my 15 degree (we’ll call them Angle Blocks ![]() ) wedges to a bottom platform (1/2" ply) and drill some 1/4" holes trying to match up with my wasteboard holes to make it easy to thread. I could essentially just that bottom platform with screw everytime if I needed/wanted, but was trying to use the 1/4 20 threadability I already had. I also added some threaded inserts into the upper portion of my “Angle Blocks” lol and that’s when I realized I probably need to redesign this some how, because trying to add threaded inserts to the lower ramp portion of the “Angle Blocks” may end up breaking that piece off. Still, this was good to get out and I think if I could still pull of the degree part I need, I already have a pretty cool design in my head that would accommodate threaded inserts no problem. Anyway…here is my rough draft for now…

) wedges to a bottom platform (1/2" ply) and drill some 1/4" holes trying to match up with my wasteboard holes to make it easy to thread. I could essentially just that bottom platform with screw everytime if I needed/wanted, but was trying to use the 1/4 20 threadability I already had. I also added some threaded inserts into the upper portion of my “Angle Blocks” lol and that’s when I realized I probably need to redesign this some how, because trying to add threaded inserts to the lower ramp portion of the “Angle Blocks” may end up breaking that piece off. Still, this was good to get out and I think if I could still pull of the degree part I need, I already have a pretty cool design in my head that would accommodate threaded inserts no problem. Anyway…here is my rough draft for now…

hmmm…i can already see a problem being, where I zero on this slant, that zero won’t always be the same as the job widens and goes either more up or down on the board

If your slot will frequently move, just set the jig up so it’s easy to line it up with the X axis & keep the workpiece parallel. Then mark your boards & set zero to the edge (or center) of the slot.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.