I’ve been meaning to share this for a while and just now getting around to it. I had always been a little alarmed by how hot the spindle and spindle motor got on longer jobs. I didn’t think that adding heat sinks would do much given the limited air flow in the enclosure and a fan would likely just get caked up with dust constantly. About a year ago, it finally cooked one of the limit switches. Of course Carbide3D overnighted me a replacement at no charge because they’re the best. Still, I didn’t want to have that happen again, so I decided to go down a different rabbit hole.

I had a few goals when I started figuring this all out.

- I wanted the whole thing self-contained. I didn’t want to have to worry about knocking over a container of coolant or tripping over hoses. I also didn’t want anything that was too tempting for my pets to chew on. I sometimes take my Nomad with me to things like Science Olympiad practices, so it needed to remain portable without having to drain and refill the coolant.

- I wanted to avoid modifying the enclosure any more than I had to. Minor changes would be OK, but the aesthetic should remain intact.

- I figured this would be a good opportunity to add a tool tray to the machine.

- I sometimes run the machine with the back cover off for longer pieces of material, so I didn’t want to lose any vertical or horizontal clearance.

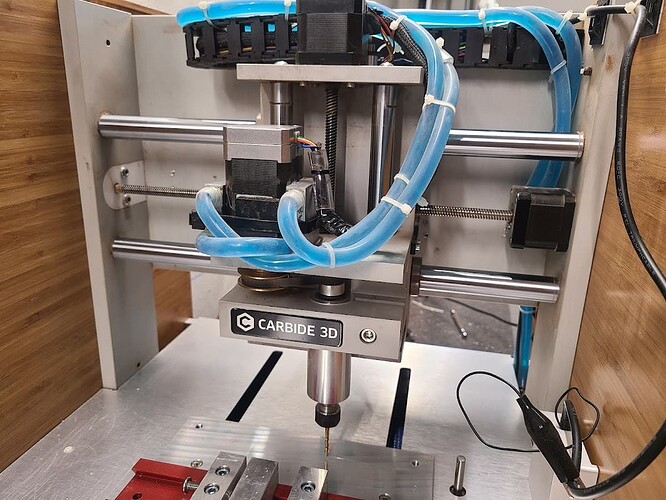

Long story short, I purchased some computer cooling components from Amazon and put the whole thing together for about $100. Here’s what it consists of:

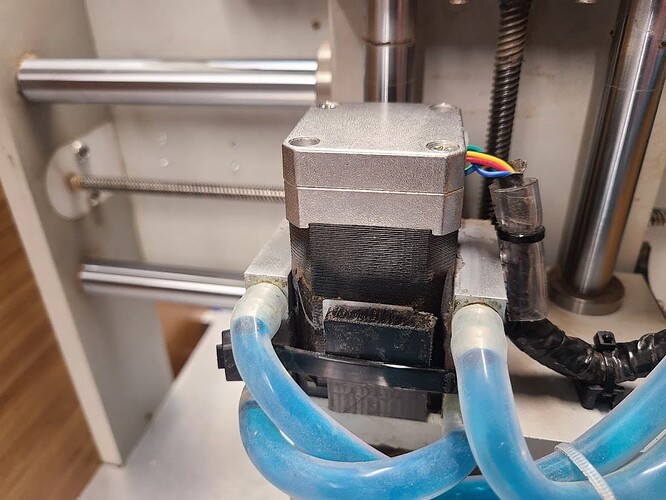

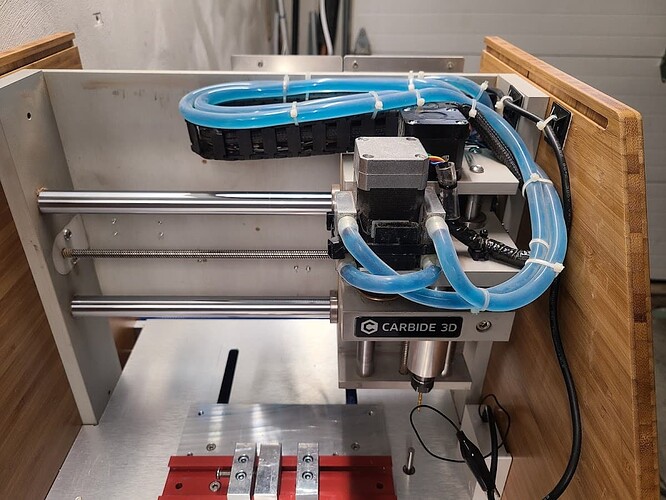

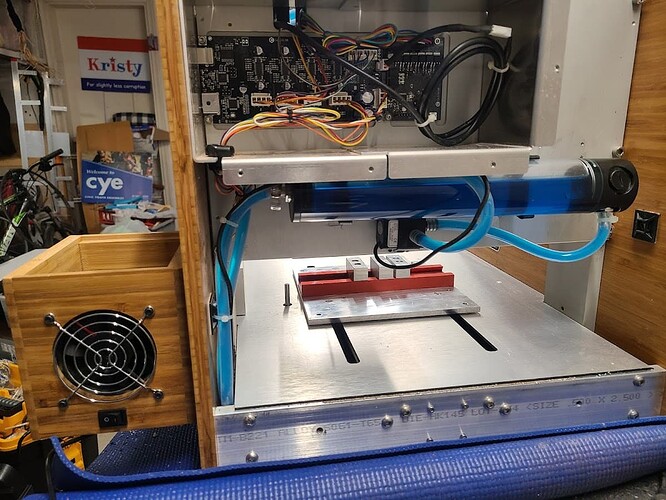

2 cooling blocks (40mm x 40mm x 12mm). They’re “temporarily” attached with a heavy-duty ziptie with a spacer in the front to keep the blocks from drifting toward the rear. I started making something more permanent, but this has been working well, so…

A bunch of silicone tubing and zipties to route it along the top of the drag chain.

It’s routed through the existing opening for the x-axis stepper motor wires and down to the underside of the machine.

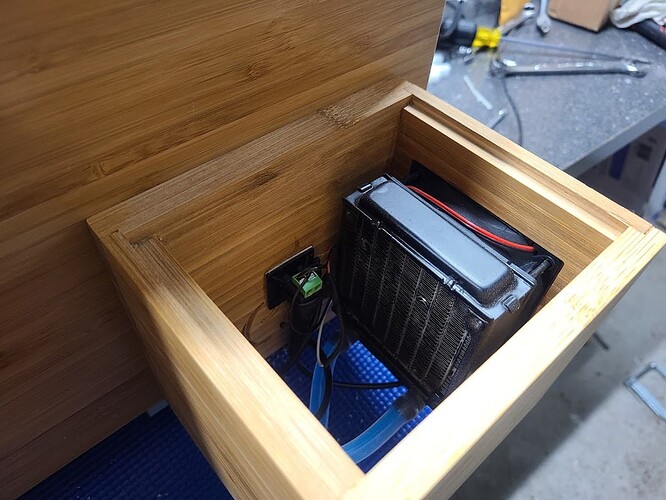

It then exits through another existing opening to go to the radiator, which has a fan attached. I made the housing out of some scrap pieces of Ikea bamboo cutting boards, so it matches the look of the rest of the machine pretty well.

In the back of the machine, I attached the reservoir and pump.

And, it topped it off with a tool tray.

That’s it, really. The whole thing is whisper quiet and the spindle and motor just barely get above room temperature when it’s running. Now for the list of things I would do different if I were starting over.

- The reservoir is much bigger than it needs to be. I later found a 1-piece pump and reservoir that would have fit to the right of the controller case that would have been perfect.

- I would have put the radiator on the left side instead of the right because the USB and power cords are kind of in the way of the tools.

- I could have used a third, larger cooling block attached to the aluminum structure of the machine instead of a radiator. That would probably be plenty adequate to dissipate the heat.

- I really wanted to have a tool tray on the machine. It’s really convenient, but all of the bits rattle while the machine is running and I could do without the extra noise.

- Items 3 and 4 above would also eliminate the extra chunkiness of having something attached to the side of the machine.