Ok so I’m familiar with wielding from my laser and using Light Burn software. I’m trying to weld a rectangle and a triangle to make a 45 for a frame I’m making. I may be doing this the hard way I don’t know if so let me know. When I weld the left side it seems to work fine 90% of the time the right side I can not get to weld correctly. I made a rectangle at 11.5319”x .625. I then made a square at .625” snapped it in a corner of the rectangle and used my line tool to draw a triangle using the square as a reference. Then moved the square and selected the triangle and rectangle then using the Boolean tool well it’s not doing it the majority of the time

Post the file and show what you want to achieve and we will walk through this with you.

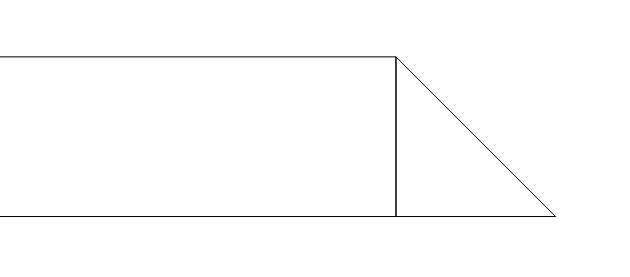

I assume you mean you are starting with something like this

Did you try all 3 types of ‘additive’ booleans? (Weld, Smart Weld, Union)

Sometimes booleans get confused when 2 objects are placed next to each other, or have perfectly aligned edges.

There are many other ways to do this. Make a larger square, rotate it 45°, position it & subtract it from the rectangle. Draw a 45° line (easy to do with any size grid), position it & use the Trim Vector tool.

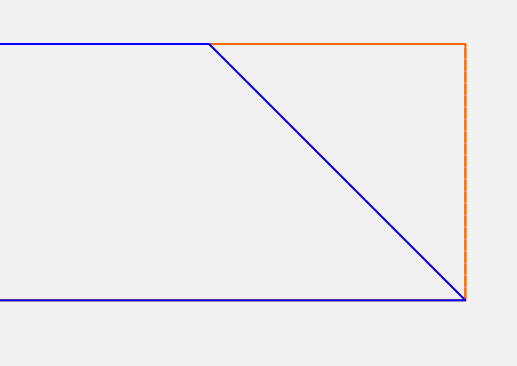

Set the grids to 0.625, or any factor. 0.125 would be my logical go-to. And position the end of your rectangle on a grid point. Now draw a shape that has the 45°, but overlaps the rectangle.

I will try that. I tried all the types of booleons

Ring Box.c2d (180 KB)

I tried it with the oversized square like you said and it worked thank you.

Good to hear. I just flipped your triangle around & tried subtract.

@Tod1d you have a outstanding way of understanding people’s situations and challenges and even more outstanding way of explaining/ serving a solution! Every time I see a response from you it’s bang on the money and top notch!

Thanks for your awesome contribution to this site!

Ken, thanks. I’m glad I can help people out. I really enjoy the problem solving part of the whole manufacturing process, and am happy to share what I’ve learned. I really like seeing the results of everyone’s projects too. I’ve seen some pretty amazing things created here. And I’ve learned a lot from the other seasoned veterans on the site as well. ![]()

This topic was automatically closed after 30 days. New replies are no longer allowed.