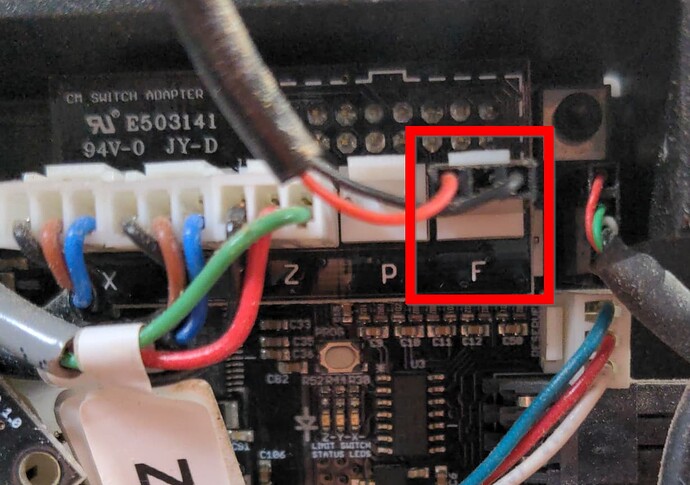

I’m sure this will depend on your board, mine is a 2.4e. On the riser board for the limit switches, there is one labeled “F”. This is technically a feed hold, pauses the run, raises the Z axis, not a true e-stop. But serves the purpose for me. Shorting the two outer pins will initiate a feed hold.

This also triggers a pause in the cncjs program - when you release the switch you’ll have to click resume in cncjs.

This post shows my estop switch setup about half way down, and also talks a little about using cncjs (but is mainly about setting up my SuperPID).

Since then I switched to running cncjs on a pi. If you decide to use cncjs, here’s a cool trick I discovered for setting up some quick macro buttons:

I’ve tried the phone interface, but honestly a little small and hard to hit the right “button” when you’re not looking at the screen. I have an old laptop running Pop_OS! that I use for the browser interface and a small bluetooth keyboard to send job commands. The tactile keys make it much easier.

Another cool cncjs feature - setup a streaming webcam through the same pi, you can display it in your cncjs browser window. When doing long multi-hour jobs, It’s a great way to keep an eye on what’s happening in the garage while I’m on conference calls. ![]()