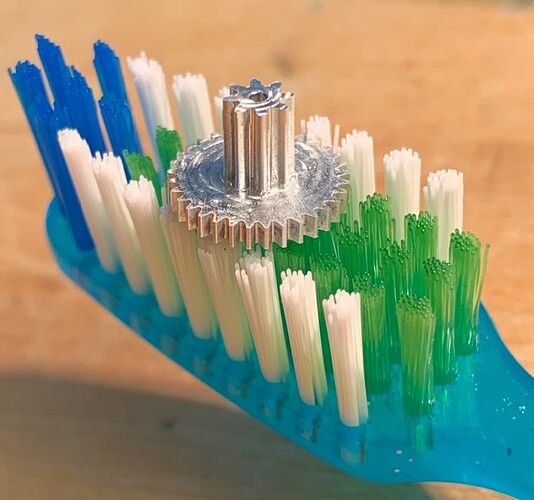

Finally got this part to come out correctly ![]() This is a duplex gear that has 0.3M and 0.4M gear teeth. The teeth were cut with a 0.4 x 5mm endmill and 0.3 x 1.5mm endmill, which is about the same diameter as a single bristle of the toothbrush, which measures about 0.25mm. Material is 7075 aluminum. Cut on my Nomad 3.

This is a duplex gear that has 0.3M and 0.4M gear teeth. The teeth were cut with a 0.4 x 5mm endmill and 0.3 x 1.5mm endmill, which is about the same diameter as a single bristle of the toothbrush, which measures about 0.25mm. Material is 7075 aluminum. Cut on my Nomad 3.

32 Likes