Still dialing things in but here are a couple vids.

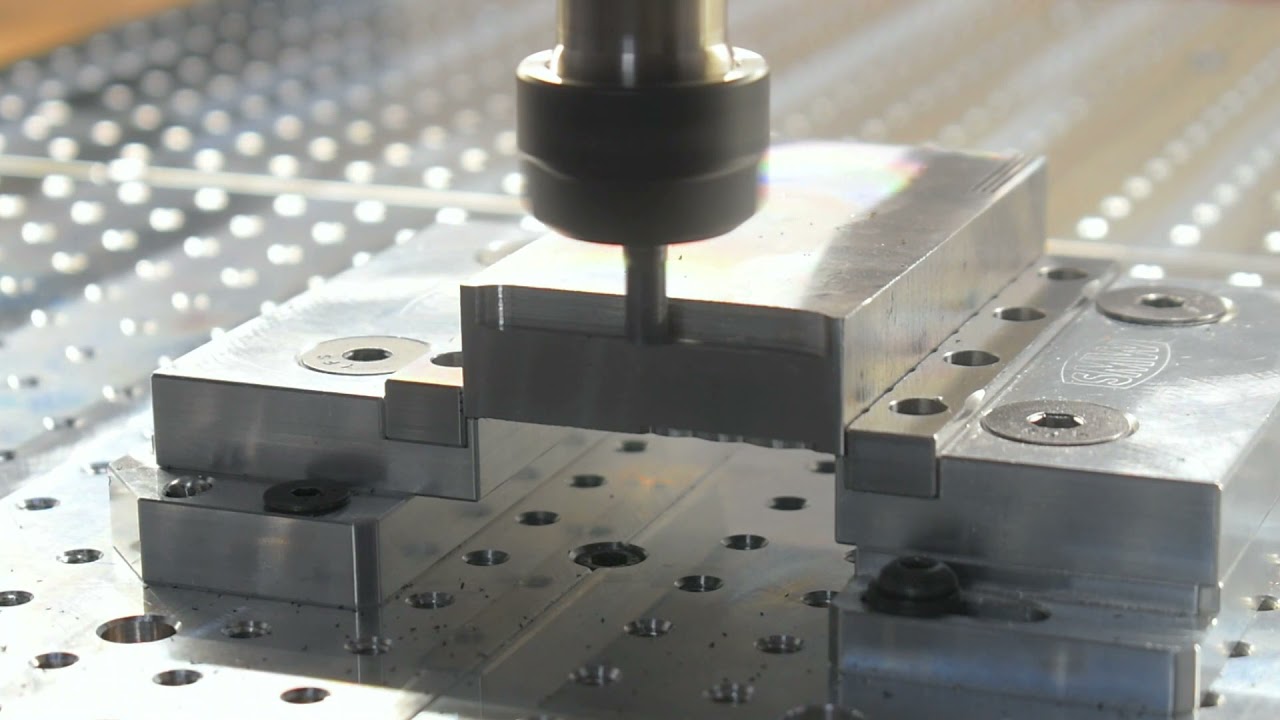

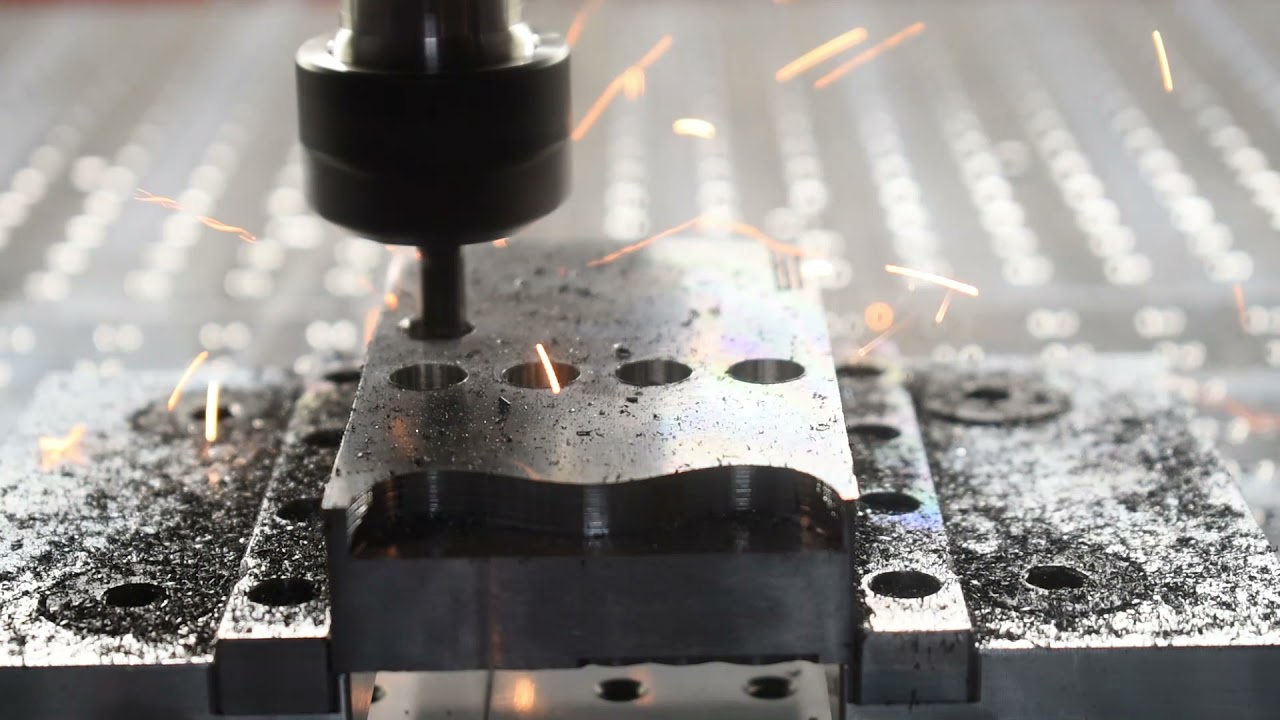

4140 Adaptive side milling and some initial boring with the same 1/4 tool. I’m probably going to lower the spindle rpm to the 8k minimum and add a light mist coolant to get things going perfect. This machine has the power but SFM limited materials will require some creativity. No feeds and speeds yet but everything looks very promising.

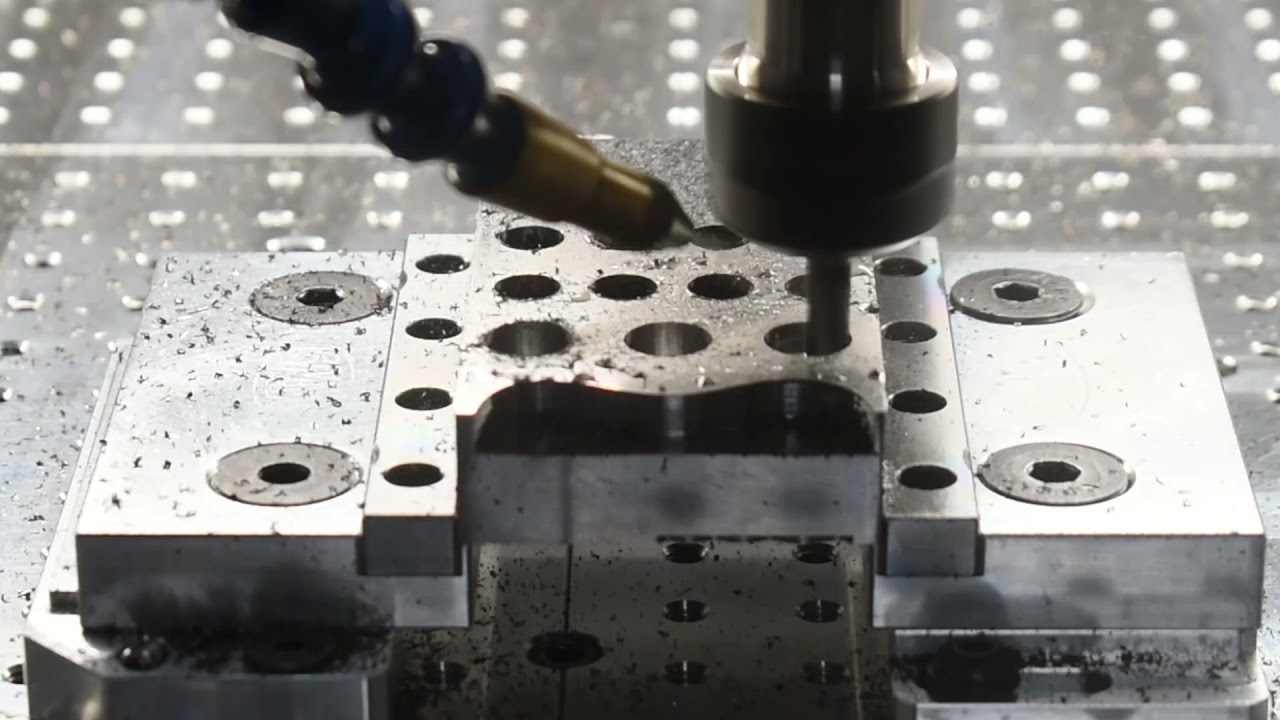

Ok, Bore take #2. 8krpm on the 1.5kw didn’t have any trouble with power delivery. Minimal mist is working well. Adjusted the feeds and speeds to be a little more aggressive to help produce a chip that will manage the heat better.