I appreciate anyone willing to help teach me how to use a CNC.

So I was thinking that I could make a name tag…so just a 3" x 1" rectangle with some text inside…

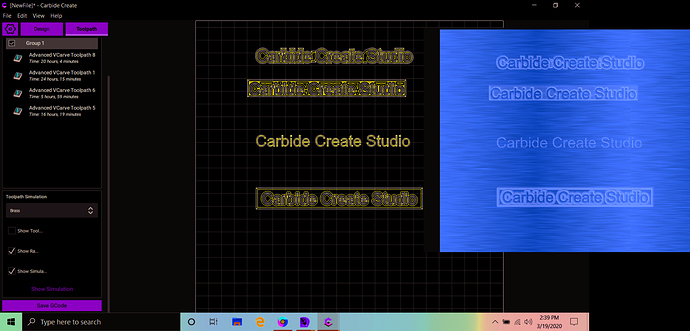

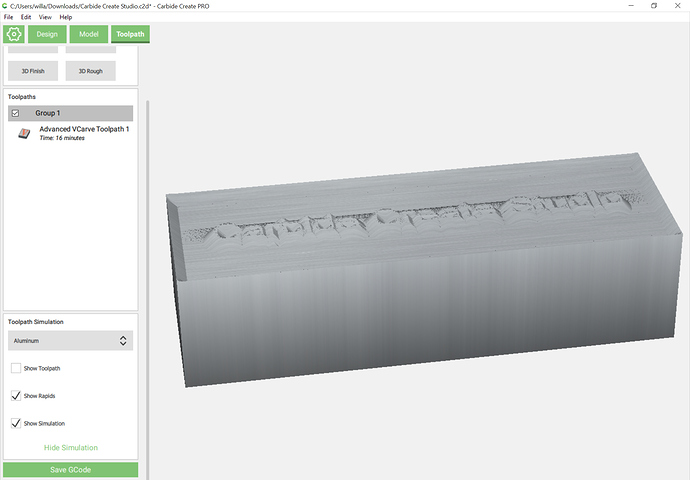

I’m attaching a picture of my tool paths and simulation.

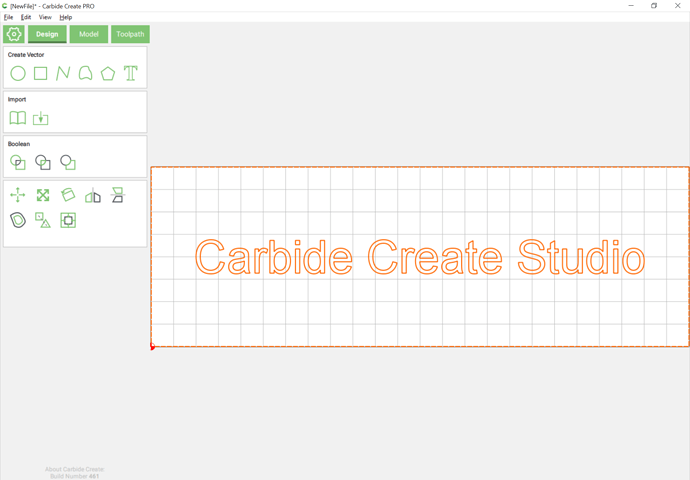

So the first thing I did was make the rectangle with text inside (technically, I started with svg with the text converted to curves/outlines and imported it into CC so it’s not technically “text”). I assumed that I could engrave the text with a vbit and then cut out the rectangle with maybe a 1/8" endmill. Easier said than done.

So I quickly realized that by putting the text inside a rectangle (second one down from the top), that this makes the text look raised in the material. So for the third one down from the top, I removed the rectangle and the text looked engraved, but then I couldn’t figure out how to cut out the rectangle that is no longer there. For the bottom one, all I did was make the rectangle bigger around the text, but now it doesn’t completely remove all the material between the text and the edge of the rectangle. And for the top one, I tried a contour around the text instead of a rectangle, but if I tried to cut out a rectangle (that doesn’t exist) around it, I would have the same problem in that all the material wouldn’t be removed.

So my first question is…how do you do text (raised or indented) and then cut out a shape around it?

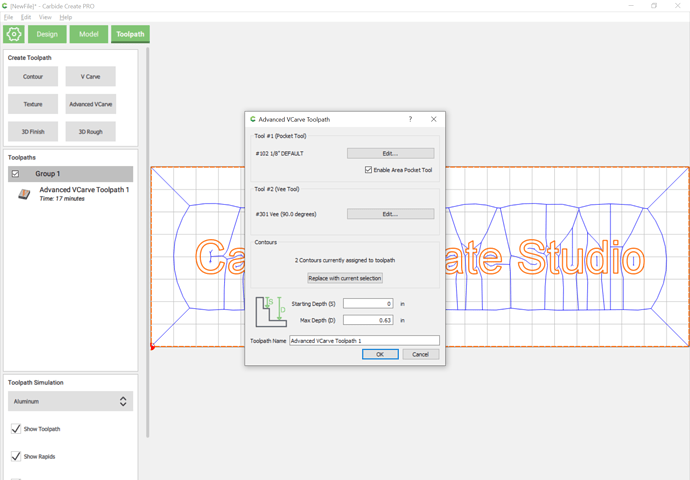

I used the recommended feeds and speeds for brass (again, for my test it is 3/8" thick) and because I did not want the text engraved to a depth of 3/8", I downloaded the CC beta that has the “Advanced Vcarve” so I could make the depth 1/8". But for this 3" wide text, the estimated times were anywhere from 5 hours to 24 hours. It couldn’t possibly take that long to engrave 3" of text with the Nomad…right? Please tell me it doesn’t.

The only reason I’m trying to use the Vbit is because this 3" text was too small to be engraved with the 1/16" endmill alone.

Thanks for any insight you can give.