This is getting expensive… What am I doing wrong? Machine is clean, bits are new, running the latest CM

This is not cheap wood and I have been carving for a short bit (9 months) I have never had this issue. Please help

This looks like skipping steps. What type of wood and whats feeds+speeds?

What kind of machine? What kind of Z Drive?

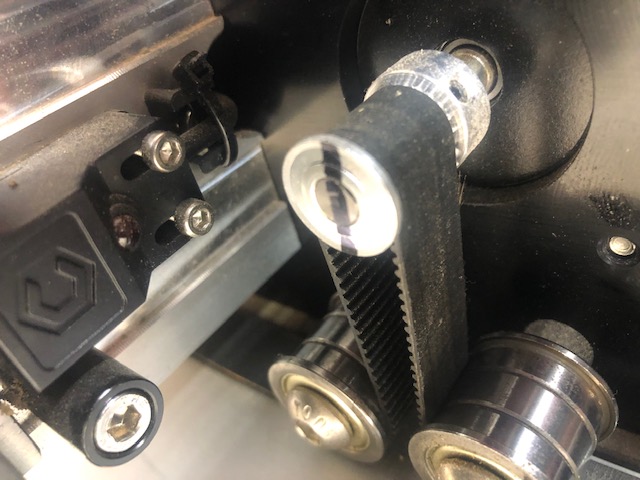

If you have a belt drive, check the pulleys on the motors. 2 set screws, both tight, one over the flat of the motor shaft. Also put a mark on it so you can easily see in the future if the pulley is loose.

It’s mahogany speed at 100 % and 18000

feed

Shapeoko Pro XXL, and I dont have a way to tighten them that I know of

Ok so the set screws are tight. They weren’t loose

This is the second carve, and it happens late in the carve

Are you able to share the file so we might look at the parameters you have set?

Pinkerton Latest 2023.c2d (2.8 MB)

I don’t know if I sent that right

Yup, Opening it now. 20 characters

I’m sure I’m stupid with this

I’m in the Army and its been a bit so there’s a learning curve again

The above is easy. If I remember one of the hex wrenches that came with the machine should fit these set screws. Check these first. If you don’t have a hex wrench that fits you should go out and purchase a good metric set cause you will get some use out of the tool.

I would then check ALL the belts for tension and tighten as needed and Im sure these will need to be tightened. If you haven’t checked/tightened these belts in 9 months you are way over due for a check and tightening.

On another note on maintenance I check every fastener in 2 - 3 month intervals depending on how much I use the machine.

In my opinion you have wiring harness connector issues and a little bit of belt tension.

If you have a remote key pad use it to test the movement and while moving give the connectors a wiggle and listen for sound changes in the motor or motors. You wont need the router running. If there is an issue in the connector or connectors you will hear a change in the sound of the motor and may even feel a jerking due to the motor stopping and starting very quickly when contact in the connector pins is lost and reconnected. You may even experience a complete stop in the motor.

Concentrate on one axis at a time and do the full movement of that axis and keep wiggling the connectors.

If your machine is still in warranty email Carbide support

Hope this helps

Anthony

Just saw all the new post.

The above makes me thing it is in the connectors due to heat buildup from a bad pin. If this is the case the connector will be warmer than normal. You should still do the testing

Anthony

Anthony, thank you for the info. Belts are new and adjusted correctly. This seems like a software issue as it always happens late in a carve.

I will check that, as I have never had that issue. Thanks

I love this forum, everyone is awesome

Do you think I need to factory reset this machine? Especially after downloading the latest version?