So I’m looking to vcarve some letters in PVC aaaaand PVC is not a suggested material for my v-bits… are there special vbits for PVC? or can I use the 301/302 or and armana engraving bits with adjusted feeds and speeds?

I have used regular V bits before in PVC it’s fine. Downcut may be a little nicer.

For the flat areas you def want to look at an O flute bit like the ones from Amana. They are specialty bits for plastic and leave a very nice surface.

The problem with V tooling is that the SFM (Surface Feed per Minute) changes along the length of the cutting flute(s), which can lead to melting.

See:

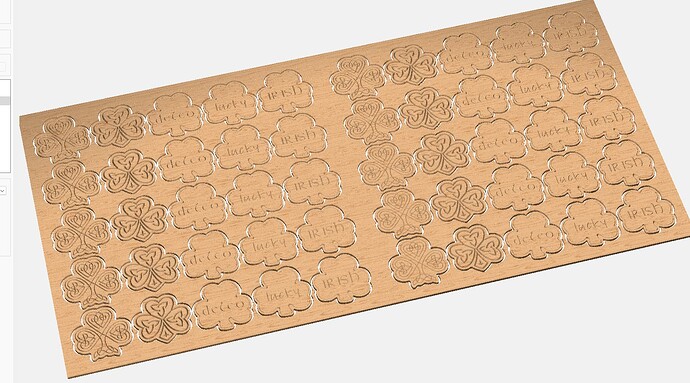

I bought the Spiral ‘O’ Flute Plastic Cutting Pack from Carbide3D ![]() to cut my shapes out (about 50 4"x4" pieces). They are both upcut bits so I’m a little worried about the 1/4" pvc lifting off the table; ill probably hold a blank sheet of MDF down on the deck, then painters tape both mdf and pvc surfaces and spray with and adhesive… plus hold downs on the edges… i may be fine.

to cut my shapes out (about 50 4"x4" pieces). They are both upcut bits so I’m a little worried about the 1/4" pvc lifting off the table; ill probably hold a blank sheet of MDF down on the deck, then painters tape both mdf and pvc surfaces and spray with and adhesive… plus hold downs on the edges… i may be fine.

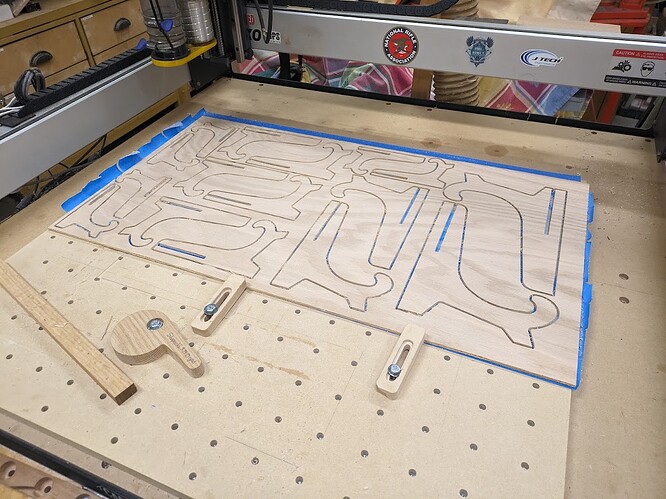

I use the painters tape a lot. Recently I cut on my SO3 XXL a piece that went from side to side. It did take a lot of tape but I did not want to have to trim all the tabs off.

thanks for this! definitely a new bookmark for me!

and i figured it had to do with melting, hopefully i can get through these carves with a good chipload and some funky air assist set-up to keep the material a little cooler…

Get some scraps to experiment. Like I said I didn’t have any issue. I probably used this though.

EXCELLENT! thanks for that!

Expanded PVC cuts well with a vbit.

Expanded PVC 60 degree v bit. The krylon fusion paint should have cured 24 hours but it was just a test.

Using an O flute for the clearing in those large areas would really clean up the flats.

I rather like the textured appearance and feel it suits the informal nature of the sign well.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.