Sorry to open that discussion again but I’ve read what I can find and I’m not sure whether the numbers I’ve seen apply to a regular size, an XL or an XXL and what performance I should expect.

I’m not trying to make a perfect machine, just wondering what is “normal” for an XXL and whether I’m doing anything wrong in the setup.

I have an XXL with the RepRap.nl kevlar belts (these are quite a bit less stretchy than the belts the machine shipped with, backlash went down to roughly 1/2 what it was before).

I have adjusted the V wheel tensions so that the wheel won’t quite turn by fingers on Y plates and Z backplate.

I have the HDZ installed, the left side V wheel on that was hard to install and is at the ‘loosest’ position in the eccentric nut and still is tight enough to not turn by finger.

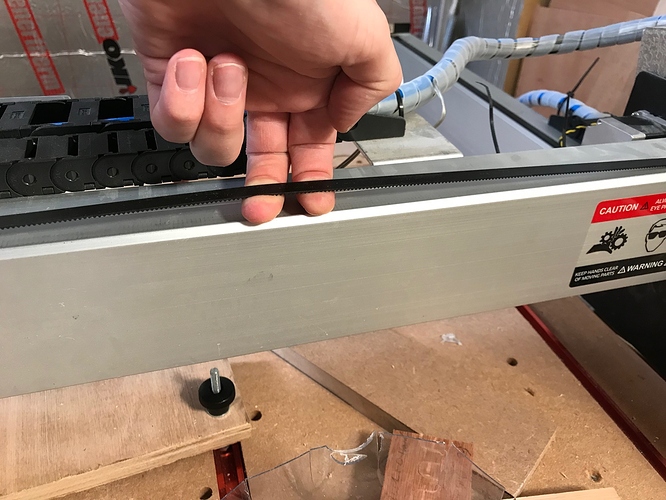

The belts are tightened as per instructions, pulled in the length of the supplied screw, I can get a couple of fingers under the X belt with the carriage off to one side.

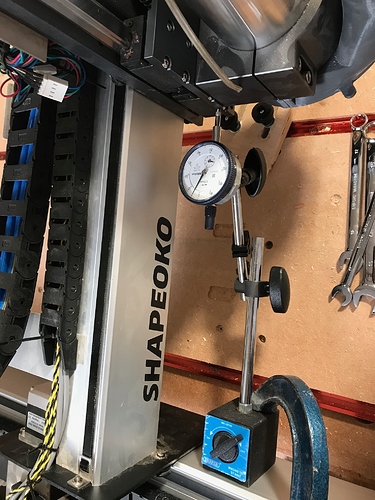

Using a (Mitutoyo 0.01mm resolution) dial gauge I’ve measured the backlash on the X and Y axes on the machine with no cutting loads and I’m getting approx 0.05mm ( 2 thou ) in both X and Y in lost motion when reversing direction. The actual movement distances are within < 1% of expected but on reversing somewhere between 0.04 and 0.07mm is lost depending on where on the X or Y travel the machine is, it’s worse in the middle and better at the ends. Steps of 0.025mm are clearly defined, accurate and repeatable in both directions on the gauge (on direction change the first couple are ~0.01mm until backlash is taken up).

Hand pressure side to side or back to front on the Z carriage can easily produce 0.2mm ( 8 thou ) either side of zero on the dial gauge.

When cutting, including spring passes I’m having to put about 0.15mm ( 6 thou ) of ‘backlash compensation’ into the toolpaths to get to measured dimensions (using a Mitutoyo digital caliper), the actual repeatability is closer to 0.05mm.

There seems to be around 0.02mm backlash on the HDZ and well under 0.05mm when pushed up or down so nothing to complain about there.

Having inspected the machine carefully, pulled the lock screws on all the stepper pulleys and re-inserted, on the flats, threadlocked and tight, checked for play between the Y plates and rails, Z backplate and X rail etc. The only place I can see this backlash is in the belts, pushing the Z carriage left and right the ±0.2mm it easily moves on the X rail the drive belt visibly moves with the carriage, at the carriage, but not at the two ends where it’s clamped down. Same for the Y belts.

So, is this the sort of backlash I should expect on the XXL?

If not, have I not tuned the belts up to a high enough note?

Anything else I’ve missed?

Thx