I recently copied a design from one program, pasted it to a new program, set all the parameters to what was needed and when I started the program, Z was 1/4” above actual Z zero (PRZ)

PRZ is position reference Zero or Part Reference Zero.

Checked all the tool parameters, checked my Depth per pass, checked my MAX depth of cut. I checked we are starting at the top of the part.

It’s just weird that it continues to do this.

Normally I would go inspect the G code when I run Mach 3 on my other machines, but here, I cannot watch the G Code while the machining is happening.

Any thoughts?

How are you setting the origin?

Post the G-code file?

Have you tried running it in a 3rd party previewer?

The origin is in the center of the part being cut.

X0,Y0,Z0

I can’t post the Gcode because it’s at school.

Hopefully I’ll remember Monday!

What’s a 3rd party previewer?

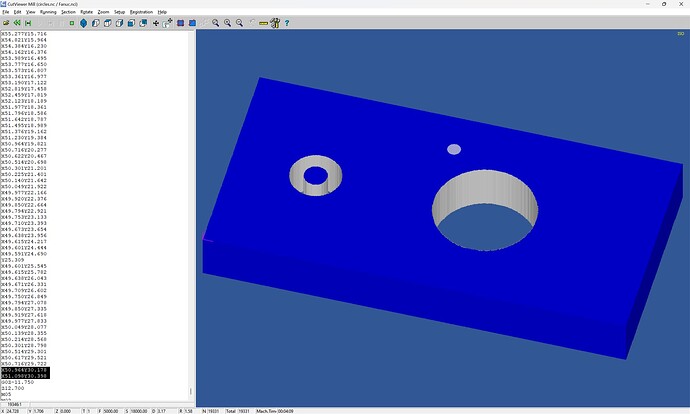

A 3rd party previewer is a 3rd party tool such as CAMotics, OpenSCAM, NCNetic, or CutViewer which will process a G-code file and afford a 3D preview of how the file should cut:

In carbide create, there is a “Show Simulation” button you can click on.

I’ll check that when I get in school Monday. I am EST time btw.

As I said, in Mach 3… I could go in an alter the G Code, save the changes and run right from there. I don’t know if you can do that in CC.

Thanks for your clarification.