I was renovating a staircase. The strings, hand rails, base rails, spindles, newel posts and skirting boards were all badly painted with multiple coats of cheap and varying trade white paints. The brush marks were obvious as was the areas that had flaked away. I wanted to strip the paint and sand the wood to a fine finish and then apply some beeswax. The issue was that much of the detail work of the whole balustrade was very difficult for me to gain access.

I have the use of an oscillating multi-tool but the 60mm depth of the head prevented it from being used for sanding between the spindles. There were some triangular sanding blocks and these were far too short to reach the spindles from the sides. I wanted a tool that would fit between the square section spindles and permit me to sand the wood. Most of the wood cutting tools that were available and able to fit the oscillating multi-tool were also too short.

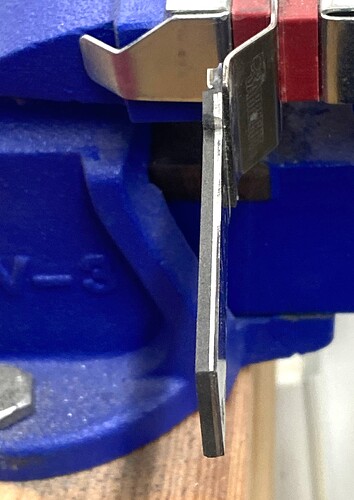

I found a an extra length wood cutting tool blade that could serve the purpose if I modified it so that it would be an effective detail sanding block. The profile of the extended cutter was almost 70mm long with a 40mm wide toothed section at the end of the 22mm wide supporting arm. I wanted the maximum length of sanding surface and after the toothed part of the blade was removed, there would be a sanding blade length of 60 x 22mm.

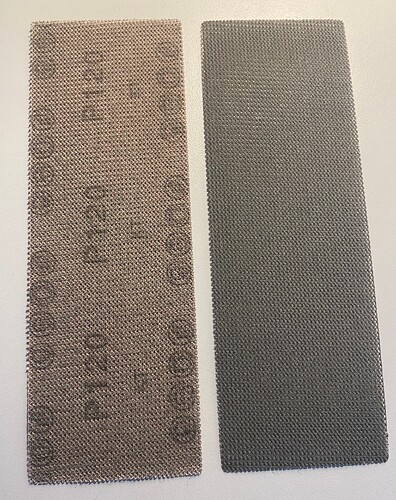

The final consideration was the thickness of the blade that was 0.64mm and it was potentially too flexible. I prepared two blades and their combined thickness was 1.31mm which produced the rigidity I was seeking. I used a rapid setting epoxy glue to join the two blades together. I had used the same glue to attach a 2mm thick rubber sheet supporting surface to the blade. The rubber sheeting had just enough give to hold the sanding mesh against the workpiece effectively. The addition of a self adhesive and heavy duty hook and loop surface completed the picture. I purchased a few mesh sanding sheets which gripped the hook and loop surface and did not move when in use. If the small sheets size proved to be problematic, I would add a layer of hook and loop to the opposite side of the detail sanding block and secure the sanding mesh from both sides of the blade.

Unmodified cutter

Modified Cutter

Heavy Duty Hook & Loop

Sanding Mesh

Rubber Sheeting Applied

Metal Smoothing

Hook & Loop Attached

Completed Project