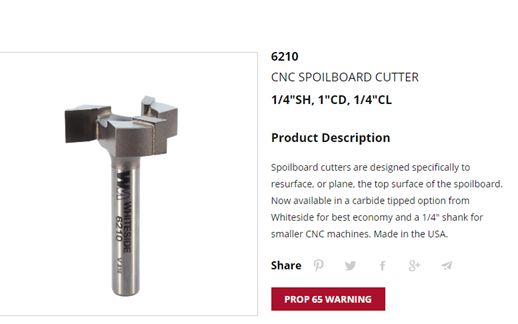

I’m a newbie and I’m starting my first project which is an outdoor sign for my father. I’m using white oak for its weather resistance. Rather than spend time hand surfacing the large board before I make the sign, I’d like to just use a surfacing bit and remove an 1/8th inch or so to level the board. I have a Whiteside 6210 surfacing bit that I bought for a future auxiliary spoilerboard, but have no idea whether this bit can handle hardwood for this project, and if so, what settings should I use in the tool database. Any advice is greatly appreciated.

I’ve used mine a few times on walnut. It worked fine, just need to do less depth per pass compared to MDF… 1mm (0.04") at a time seemed to work fine @ 30ipm

note that surfacing bits don’t “plunge” well so I would set the plunge speed to something like, 10ipm or less

Thanks a lot! Excellent advice. I’ll give it a try.

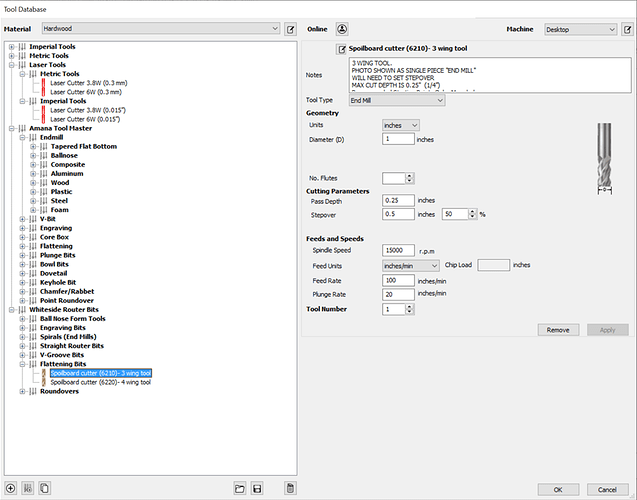

I use the Whiteside 6120 bit to surface my spoil board. Whiteside said to use 100 IPM but here is my settings and would work for surfacing your work piece.

I used mine on white oak end grain for a sign. I agree with plunge rate white oak is tuff for this bit to bite down on.

here is the result.I love the 6210 and use it often. Hardwood is perfectly fine. I would note though, I avoid vertical plunging when possible. If you cannot clear the workpiece for your surfacing paths, try to incorporate a very gradual ramped plunge.

It’s not a center cutter, so plunging is not a good idea.

Whiteside now has tool libraries for Vectric and Fusion360.

It’s worse than useless for this cutter in Vcarve though!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.