Hi @GIban671,

Maybe going through that thread could help you, I reported the exact same difficulty a while back and it was an interesting discussion about deflection, and how to deal with it.

It’s like @mikep and @neilferreri said, it’s deflection. Even with a machine that is ok from a mechanical standpoint, the endmill+machine deflection can end up causing that groove. I have written a short bit on this here.

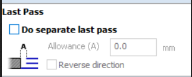

The best way to address this is to go for an oversize/undersize (depending on whether its an outside profile cut or a pocket) cut first, and then a second cut to shave off the remaining material from the perimeter of the cut, to get to the right dimension: during that second cut, since the endmill will be removing only very little material, it will not deflect at all, and give you a nice even finish all around the piece. In CC, this takes a bit of adding extra geometry and toolpaths, but I see you are using VCarve and it has a great little option that you can use to deal with this: check the “Do a separate last pass” box in the profile toolpath options:

setting the allowance to 0.5mm for example (there is even the option to reverse the direction of the cut for that last pass only, since sometimes it gives a better finish, i.e. it uses climb milling for most passes, and conventional milliing for the last pass)

Another way to is add a lead-in/lead-out to the toolpath (check the “Leads” option in the toolpath menu), it will take care of that groove too.

VCarve is nice, isn’t it ?