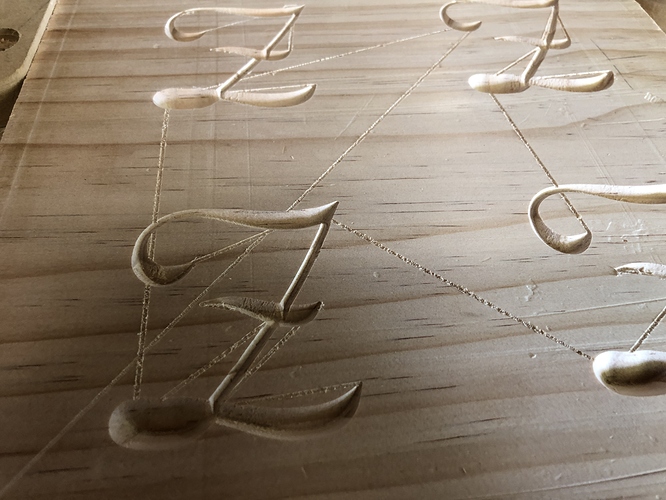

Created coasters and using cc316. Simulation shows everything okay Using v bit 301 set everything to be cut 1/2 in pine. Letter cut fine just ended up with the lines.

Please post the file.

V endmills are only properly previewed in Carbide Create when using V carving toolpaths: https://docs.carbide3d.com/assembly/carbidecreate/video-tutorials/#v-carving

The usual cause of extraneous lines on the surface is insufficient retract height

coasters.c2d (890.4 KB)

this is the CC 316 file

Still not sure what you mean by lines. Some observations:

- safety/retract height is set to 0.157 in. which should be fine ,so long as the stock surface zero is set more than half an inch below top travel limit

- you have one toolpath set to cut out 4 profiles — I’d suggest using 4 separate toolpaths — you’ll get more efficient movement, also consider adding geometry around to cut as a pocket down to tab depth, see: Adding geometry to cut as a pocket with a finishing pass

- your stock thickness is set to 0.5 in., but you have the profile path cutting to 0.75 in. deep — okay?

If that doesn’t address your concern, please let us know the specifics of the lines and we’ll do our best to help.

thank you I will look it over again n make some corrections n see what happens

Would really help to see a photo of the problem you’re seeing.

What is your retract height set at in the job setup tab? In the 3XX the retract height is in mm not inches.

Insufficient retract height probably — you have it at 0.157in

Or you’re losing Z-axis steps: https://wiki.shapeoko.com/index.php/FAQ#Mechanical

Is your spoil board completely level? How about the thickness of material. Variations of material thickness are common place.

How are you zeroing your v bit? Should barely touch the material. Enough to let paper spin on axis but not so tight the paper won’t spin.

I only ever set my retract height to 2mm. Or .079 in. And never have this issue.

Although I don’t have clamps above my surface material. So I run low.

So retract not being high enough Isn’t the only issue for this effect. Something else in the setup is more than likely off.

“Simple” resolution is to increase retract height. But I would look more into the machine.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.