I’ve been experimenting with wooden inlays for some time now and was just curious what is everyone’s preferred depth for the pocket when doing a project like a cutting board or something that gets a lot of use?

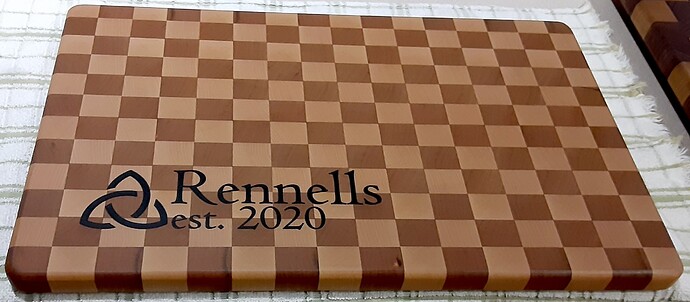

The cutting board’s I’ve done with simple text (not v-carved) inlays, 1/8". Inlay’d wood for some and epoxy for others. These were done as housewarming gifts. I don’t expect them to be heavily used as cutting boards and so not require resurfacing.

Could be wrong though!

Example epoxy and engrain board :

(and might even be a bit shallower than 1/8" – didn’t really take notes.)

I appreciate it, but I’m more so curious about wooden inlays, just because I’ve heard of people going as deep as .30 for the pocket. Was unsure if it was for a durability reason or if a shallow pocket is just as strong

I don’t have pictures of wooden inlay work handy but I kept the same 1/8" (-ish) because I had 1/8" material handy. I’ve also gone shallower. Most of the veneer I have is around 1/40" thick but I’ve also made my own “plywood” out of it using three layers which works out to be a bit thicker than 1/16". I suppose if all I had on hand was 1/4" or 6mm material I’d pocket deeper.

I’ve noticed that cutting board inlays that are very “fancy” and done with v-carve do have portions that appear quite deep, greater than 1/8". This may have more to do with geometry of the inlay technique and keeping the sharp corners than durability.

I’ve done oodles of inlay work, not V-carved. I’ve inlaid wood, MOP, silver, gold, stone, etc. All these have been 1.2 to 2.5 mm thick. However I’d probably go deeper on a cutting board since, some day, I’d probably want to resurface it. 0.30", if that’s what you mean, seems like overkill. Then again, although all my inlay work has withstood the test of time, it’s been in guitars and jewerly boxes not subject to water. For a cutting board, I’d probably go 3 - 5 mm in depth with wood inlays.

Since you mentioned guitars, this is another subject that interests me… do you use your CNC to cut out electric guitars? I’ve been trying to find layouts/ prints that I can use to make my own, if you have any recommendations it would be appreciated!

The majority of the guitars I’ve made were acoustic and done before owning my Nomad. Lots of folks do use the Shapoko, and similar, to cut bodies but I wouldn’t bother except for mass production. One thing I certainly would do if making another guitar is to mill the fret slots and perform the inlay with CNC.

Just depends. If v-carve, I use the standard settings whereby max depth is like 0.1" or so.

For straight, end-mill inlays, especially in cutting boards, I will usually to 0.25".

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.